Nolato has taken injection molding to the next level by using scientific injection molding (SIM), which ensures the highest-quality product over a program's life cycle, regardless of molding machine, material or manufacturing location.

Contact us

Sending Email...

SERVICES

Scientific injection molding

We use scientific injection molding techniques to develop process characterizations that guarantee repeatable molding, despite expected variation in materials and processing equipment. Injection molds are put through our rigorous statistical validation process to achieve the same critical molding parameters, regardless of manufacturing location or machine.

Avoid production backlogs and improve time-to-market

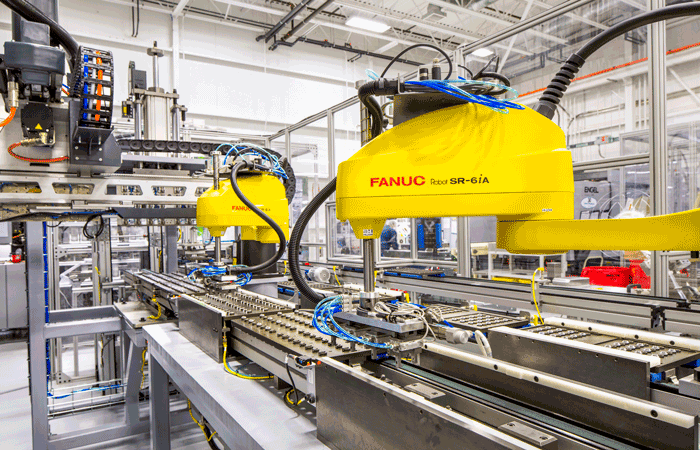

Cut production machine downtime in developmental work with our dedicated facility and a focus on lean manufacturing, using electric molding machines and press-side automation.

Cutting-edge injection-molding techniques

The key steps involved in scientific injection molding include mechanical cycling, short-shot analyses and fill studies, viscosity curve and gate freezing, balancing of fills between cavities, high/low challenges, weight studies and use of cavity pressure transducers.

Development of robust processes regardless of manufacturing location

We build entire manufacturing cells in a dedicated non-production facility. These are then delivered to a production plant as a completely automated and validated system.

Ensure high-quality, repeatable production

Scientific injection molding offers consistent product quality, despite expected variations in molding materials and equipment.

Mold-specific rather than machine-specific process development

Our molds are put through scientific process development and validation testing, so that when the molds are sent to a production facility, the process is duplicated rather than developed from scratch.

Proven methodology with rigorous statistical validation

Nolato's systematic approach using the principles of scientific molding, coupled with rigorous statistical validation, ensures a repeatable process for the life of the program.

TECHNOLOGY

Advanced scientific injection molding technology

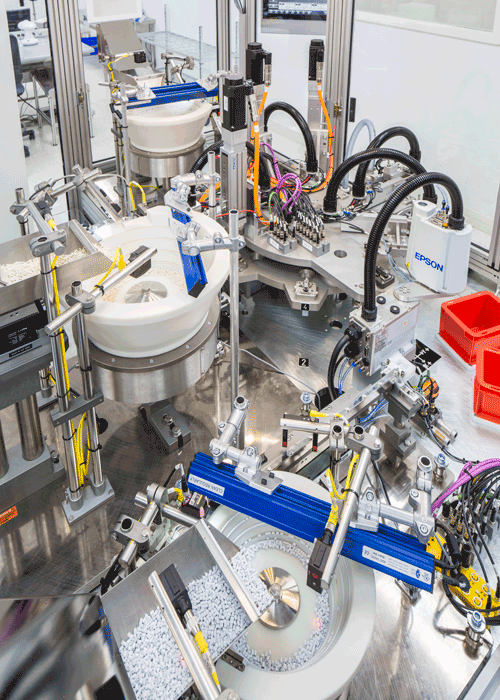

We use advanced scientific molding technologies to maximize manufacturing efficiencies and offer our customers a one-stop supply chain solution. To reduce costs, improve quality, and streamline our customer's supply chain, we invest in robot-assisted molding technologies for both thermoplastic and silicone injection molding, including multi-shot/multi-material molding, automated insert molding and micromolding.

PRODUCTION

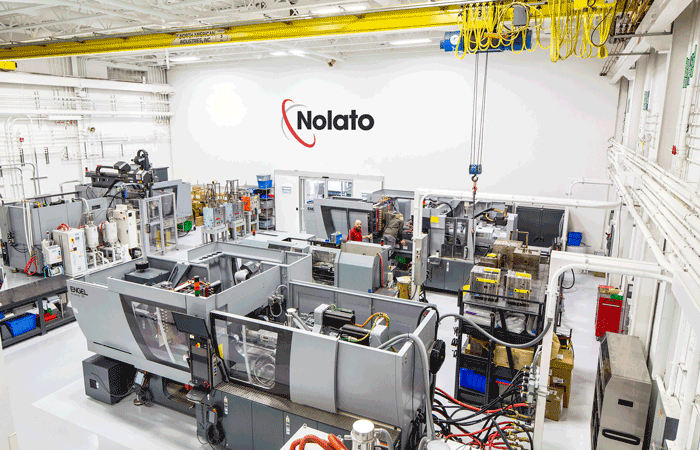

Dedicated SIM facility to support global Nolato manufacturing network

Nolato's process development and training center establishes production processes for new molds to be introduced at our Nolato production facilities. It also supports scientific process development and validation for entire manufacturing cells, including machines, molds and automation.

You might also be interested in

MEDICAL EXCELLENCE

Creating world-class operations

Medical Excellence is our way of creating world class operations inspired by the Nolato spirit, our strategies, quality standards and our lean processes and tools. Together, these elements create a framework for managing resources efficiently and increasing value for our customers.

NOLATO FOR EMPLOYEES AND CUSTOMERS

Employee and customer advancement

Nolato is committed to the development of our associates wishing to further their manufacturing skills, as well as our customers looking to learn more about injection molding.

STORIES

Sustainability an integral part

For Nolato, sustainability centers around social and environmental work which we see as an integral part of our financial value creation.