Nolato is a global full solutions provider and contract manufacturer specializing in product and process development through final device assembly and fulfillment. Our offering covers the entire value chain, from development to high-volume production and beyond.

Contact us

Sending Email...

SERVICE

Full solutions provider and contract manufacturer

Nolato's contract manufacturing capabilities allow our customers to take advantage of a single-source manufacturer for their products. As a concept-to-market manufacturing partner, we offer advanced product development, process development, tooling, molding, assembly, and packaging services. Working with a partner that truly understands their product from start to finish ensures better value for our customers. Our shared expertise across more than 30 manufacturing facilities strategically located around the world means we are never far from our customers.

Product development and design for manufacturing (DFM)

Through early involvement in projects, we provide product design, tooling, assembly and decoration, and continuity of supply to reduce long-term costs, improve quality, and speed up projects. We create technical solutions that give products unique features, minimize cost and reduce environmental impact.

Precision tooling

Nolato specializes in the design, build and validation of complex injection molds for thermoplastic, liquid silicone rubber (LSR), metal and rubber products. Our in-house mold-making capabilities offer advanced program quality control and improved time to market.

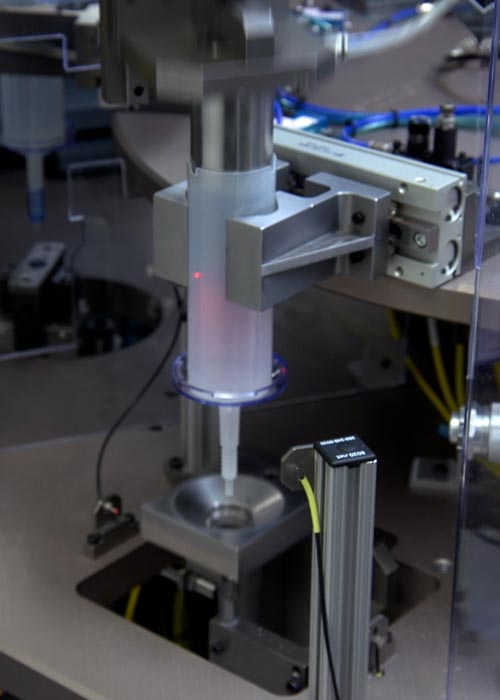

State-of-the-art molding

Our diverse portfolio of advanced molding capabilities includes injection molding, multi-shot/multi-material molding, insert molding, IMD/IML, micro molding for thermoplastics, LSR and more. Read about all our services.

A global network of full-service solutions manufacturing

Our more than 30 advanced manufacturing facilities around the world are strategically located so that we are never far from our customers. Nolato also meets all relevant certification standards, which is of significant value to our customers.

Advanced secondary operations

Nolato offers

- manual, semi-automated and fully automated assembly solutions

- most decoration technologies, including fully automated painting lines

- packaging capabilities such as form-fill-seal, tray-lidding, and pouching

- support to our clients in selection of vendors and the process of getting products, manufactured by Nolato, sterilized with a third party

TECHNOLOGY

Efficient and innovative contract manufacturing solutions

Specializing in critical applications that are shipped directly to our customers' distribution centers means there is zero tolerance for defects. So every step of our manufacturing process uses cutting-edge technologies. From virtual prototyping and mold flow analyses to precision mechanical assembly and automated inspections, Nolato ensures the highest product quality.

PRODUCTION

Full-service manufacturing capabilities

Nolato is a full polymer solutions provider. We partner with our customers to transform a product design into a high-volume, zero-defect manufacturing process. Our state-of-the-art Class 7 and 8 cleanrooms feature advanced robotics and vision inspection systems to ensure consistent quality, and our in-house tooling, molding, assembly, decoration and packaging capabilities complete our one-stop-shop manufacturing portfolio.

You might also be interested in

MEDICAL EXCELLENCE

Creating world-class operations

Medical Excellence is our way of creating world class operations inspired by the Nolato spirit, our strategies, quality standards and our lean processes and tools. Together, these elements create a framework for managing resources efficiently and increasing value for our customers.

SERVICE

Micromolding

Micromolding is a concept used in making either extremely small components or parts from temperature-sensitive materials.

SERVICE

Injection molding of silicone

Nolato has over 40 years' experience in delivering cost-effective solutions for precision liquid silicone rubber (LSR) components and assemblies.