Nolato has over 40 years' experience in delivering cost-effective solutions for precision liquid silicone rubber (LSR) components and assemblies.

Contact us

Sending Email...

Contact person/s

Kristian Larsson

Sales

+46 768 88 00 20

SERVICE

Injection molding of silicone

Silicone injection molding offers exciting design and molding opportunities. Nolato can help you take advantage of LSR's design flexibility, and our advanced silicone molding technologies can cut your program costs and increase component quality.

Diversity in applications

LSR is used in many mission-critical applications where failure is not an option. Nolato specializes in molding tight-tolerance silicone components with exceptional shot-to-shot repeatability and zero-defect manufacturing.

Design flexibility

Silicone offers the ability to fill part geometries with tighter tolerances than are possible with a thermoplastic elastomer. Precise features, varying wall thickness, reduced likelihood of sink, small undercuts and negative draft are all possible with LSR.

Biocompatibility and performance properties

LSR is ideal for short- and long-term human implants because of its bacteria resistance, ease of sterilization, and odorless, tasteless and stainless characteristics.

Automatic silicone molding

The best way to decrease contamination is with automatic molding. Cycle times remain consistent, which is essential for liquid silicone molding, and it eliminates machine operators, reduces part variability, and lowers program costs, all while increasing quality.

Multi-material molding

Our specialty in molding multi-material components such as two-shot, insert, or overmolded parts can help expand your product's performance options. Take advantage of Nolato's global injection molding services.

Sustainable product life

Silicone is unaffected by environmental factors and remains attractive throughout the device's life. It does not lose transparency with age or exposure to UV light, moisture, or heat, and is resistant to scratches, cracks, and breaks.

TECHNOLOGY

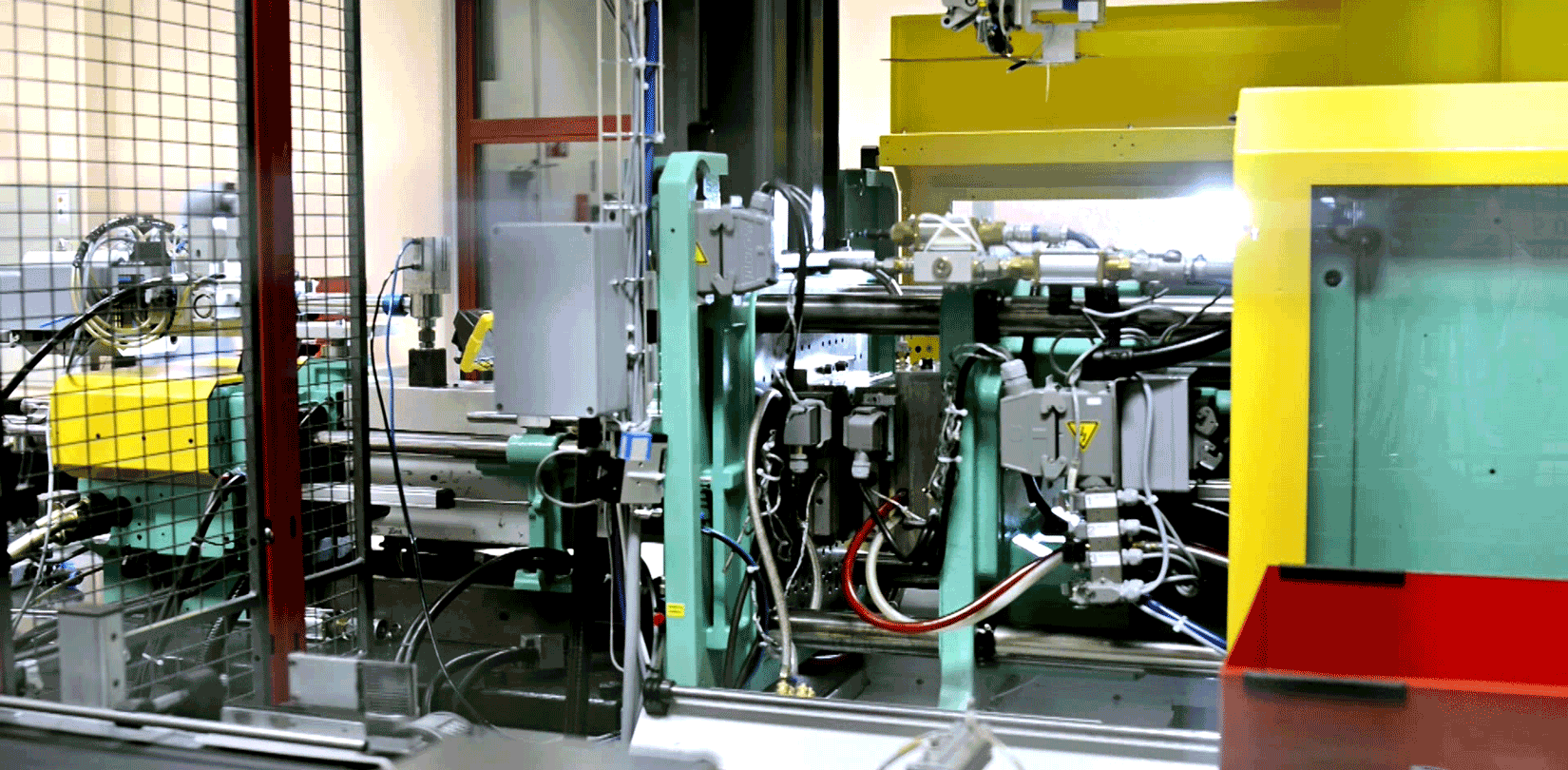

Automatic LSR and HCR injection molding

Our LSR cleanrooms are equipped with all-electric and hybrid molding machines, which allow us to match the best machine to each prototype and production application. We use robotics that operate within the machine envelopes, enabling both insert-loading and molded-part extraction. Screw and barrel assemblies allow for the molding of parts from fractions of a gram to larger details, providing a wide range of silicone injection molding capabilities. We are also able to manufacture HCR (high consistency rubber), using fully automated injection compression techniques.

PRODUCTION

Concept-to-market silicone manufacturing

Nolato's silicone divisions offer full-service LSR manufacturing capabilities, including product development, prototyping with production representative tooling, advanced LSR mold-making, cleanroom silicone injection molding, multi-shot/multi-material molding, and secondary operations for single-source production.

You might also be interested in

MEDICAL EXCELLENCE

Creating world-class operations

Medical Excellence is our way of creating world class operations inspired by the Nolato spirit, our strategies, quality standards and our lean processes and tools. Together, these elements create a framework for managing resources efficiently and increasing value for our customers.

SERVICE

Micromolding

Micromolding is a concept used in making either extremely small components or parts from temperature-sensitive materials.

SERVICE

Laser-activated bonding

Laser-activated bonding is a technique developed by Nolato for assembling components of display screen panels and other applications.