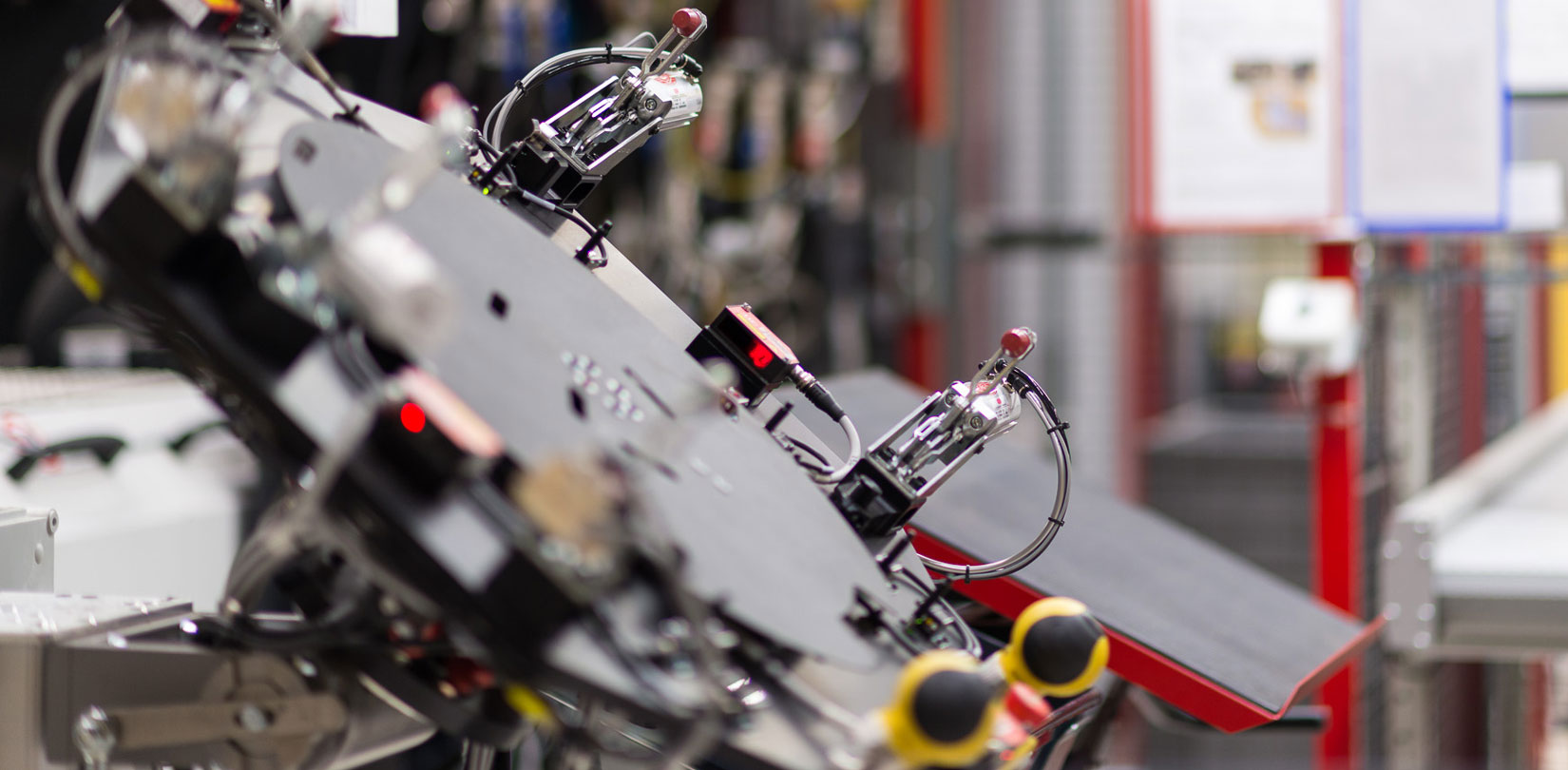

Located in Gothenburg in western Sweden, Nolato Plastteknik offers advanced full-service injection molding and assembly solutions for leading industrial customers.

GROUP COMPANY

Nolato Plastteknik

Our offering includes advanced injection molding of thermoplastics, and efficient component assembly. We work closely with our customers' development specialists to support the whole process, from concept to finished product. Our customers operate in a wide range of industries, including packaging, telecom, HVAC and engineering.

EXAMPLES OF PRODUCTS

- Brackets

- Covers

- Plastic packaging

- Ball bearing cages

Our site

With a production area of 14,500 m2, our site offers everything from product design support to high-speed and high-volume manufacturing.

Contacts

If you would like to find out more about Nolato Plattekniks's services and products, please contact our team member below or use the form at the bottom of this page.

Martin Kores

Sales

Certifications

Certified environmental management systems are an important element of Nolato's sustainability work, and all companies are certified, acquired companies get a grace period to become certified. Download our certificates here.

TRADE FAIRS & EVENTS

Meet Nolato

There are several opportunities every year to meet us at trade fairs and events around the world.

CAREERS AT NOLATO

Join our team

The Nolato Group consists of three business areas that develop and manufacture products in polymer materials such as plastics, silicone and TPE. We offer stimulating roles and good development opportunities in an international work environment.

Stories

STORIES

Design for disassembly

The most effective way of making a plastic product environmentally friendly is to make sure that the products is recycled. When it is not possible to design the entire product in the same material it needs to be easy to take apart.

STORIES

Agrivoltaics introduced to solar farm

Combining both agriculture and solar power generation — called agrivoltaics — is a burgeoning innovation that optimizes the productivity and efficiency of land use. Read more here.

STORIES

Simple route to a sustainable future

At Nolato Cerbo in Trollhättan, the everyday, simple route to a sustainable future is also important. That’s why all employees are offered the opportunity to buy a bicycle – standard or electric – via the company for commuting to work.

Would you like us to contact you instead?

Please fill in the form and select your preferred method of contact and we will get back to you as soon as possible.

You might also be interested in

INDUSTRY

Automotive

Nolato are a solutions provider for businesses that need a high-tech partner with in-depth experience and advanced capabilities in the development, production and assembly of automotive products.

SERVICE

Injection molding of plastics

Nolato's high level of molding expertise, cutting-edge machinery and continuous process monitoring allow us to ensure consistent and efficient production with high quality output.

STORIES

Mass balance cuts carbon footprint

Mass balance for plastic is a useful way of slowly introducing renewable raw materials by mixing them with fossil raw materials to gradually phase them out of a product