Nolato has extensive experience in various cutting techniques.

Contact us

Sending Email...

Contact person/s

Min Lin

Far East Asia

+886 963079148 (TW), +86 18402155106 (CN)

SERVICE

Die-cutting technologies

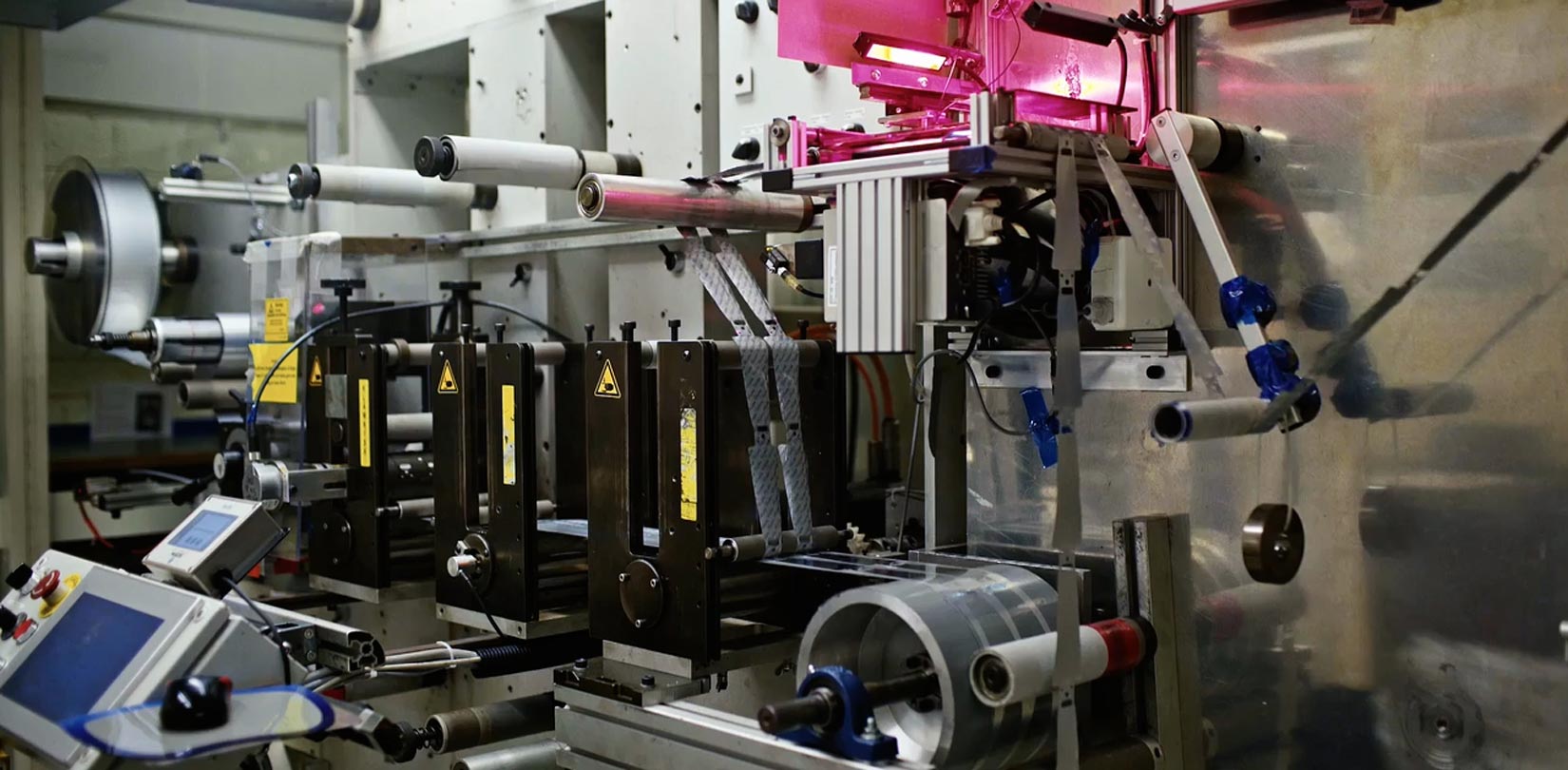

We offer world-leading quality and capacity in traditional and advanced die-cut manufacturing, in both standard and cleanroom environments.

Manufacturing

In a custom gasket manufacturing technique, die-cutting combines proven technologies with efficient approaches to gasket fabrication.

Specific techniques

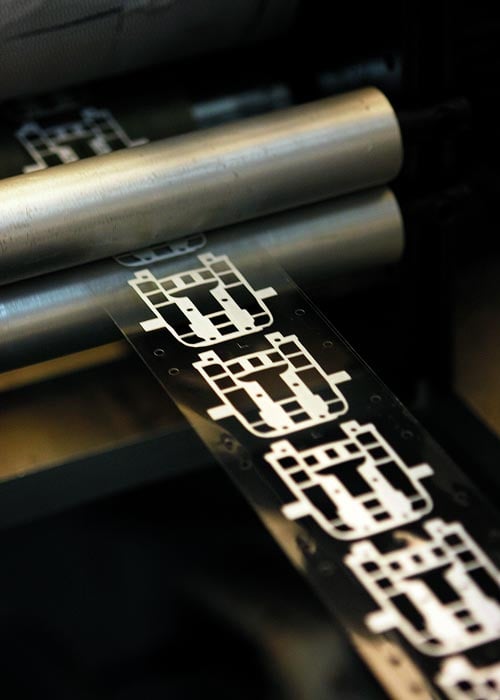

Specific die-cutting techniques vary, but most methods involve two core components; a metal tool called the die, and the die-cutting machine itself.

Converted products

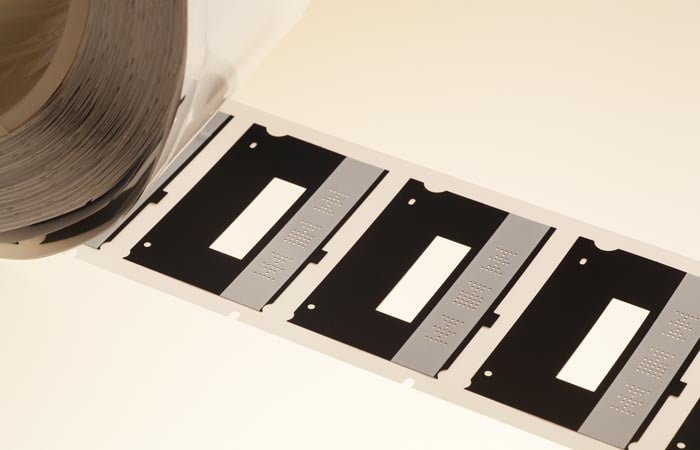

Converted products are often supplied on rolls or sheet forms. Tape is the most common material, while thin metal foils, textiles, thin foam materials and various plastics films are also used.

Laminating

Two or more materials can provide properties that a single material cannot offer. Tape is often one of the materials laminated with plastics, textiles and foam materials or metals.

Laser

A laser technique enables quick tool-free prototyping and mass production.

Assembly

We provide assembly of various die-cut products with other mechanical components as module delivery.

TECHNOLOGY

Level of precision

Our technique offers an impressive level of precision at high speeds, which means low production costs for large volumes.

PRODUCTION

Custom gaskets

Die-cutting can create a range of custom gasket sizes with tight tolerances. Part volumes can range from low-volume prototypes to high-volume production runs.

You might also be interested in

SERVICE

Assembly solutions

Our expertise and experience in assembly solutions allow us to always offer the right degree of automation.

SERVICE

Dip molding

Nolato's extensive experience in dip molding with advanced process control ensures consistent output of high-quality products.

SERVICE

Extrusion

We offer extrusion of medical-grade tubing with cleanroom production, as well as cut-to-length, tip-forming assembly of complete devices and other solutions.