Our global TDC functions as a hub within Nolato to support customers in the development of new products, from project launch to industrialization

Contact us

Sending Email...

BUSINESS NEWS

Our Technical Design Centers merge

Nolato’s Technical Design Centers in Europe, Asia and North America merge

A key aspect of Nolato’s business involves us sharing our expertise in design, materials and high-volume production to support our customers in their product development. By applying our end-to-end approach, experience and skills in advanced technologies, sustainable solutions and cost-effective production, we can help customers in the project phase develop new products with optimal functionality, lower environmental impact and reduced production costs.

Customer-specific products represent a significant portion of Nolato’s manufacturing. This means that it is the customer’s ideas, preferences and needs that form our starting point. By supporting customers with our experience and expertise in advanced technologies, sustainable solutions and cost-effective production, Nolato can help ensure that the customer’s products have optimum functionality, that high-volume production is more cost-effective, and that the products have a reduced climate impact and are easier to recycle at the end of their useful lives.

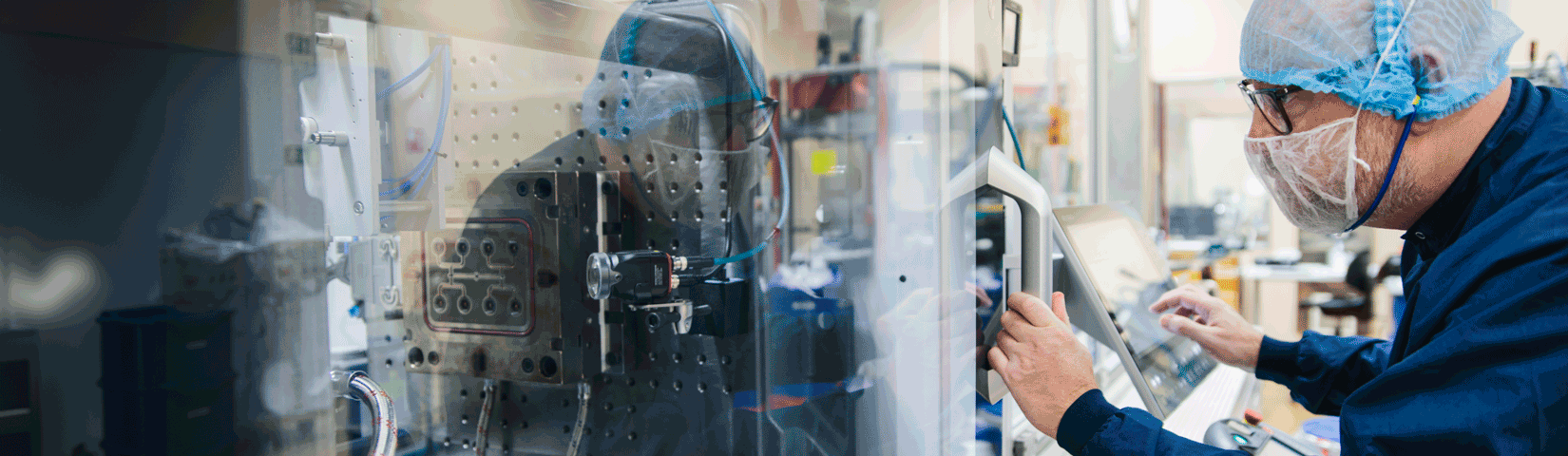

Much of this work takes place at Nolato’s Technical Design Center (TDC), which employs some 50 people in Europe, North America and Asia. TDC is also home to Nolato’s 200 or so in-house toolmakers, who focus on developing and manufacturing new molds that require various specialisms and who can also support local units by carrying out more extensive maintenance and upgrades to existing molds.

Supporting customers at the development phase is an important part of Nolato's operations.

Important foundation for success

“Nolato’s holistic concept is an important foundation for the company’s successes,” says Patrik Ingvarsson, TDC EU Director. “Although Nolato’s main focus is on production itself, supporting customers during the development phase is an extremely important and growing part of the business.”

There has been a TDC focused on the medical sector for many years now. It was based on the technological successes Nolato had had since the end of the 1990s, with an equivalent resource for the development of mobile phones in Kristianstad in the business area known at the time as Nolato Telecom. During the first decade of the 2000s, our Integrated Solutions business area built up resources in China, with an emphasis on consumer electronics. When Nolato later became established in the US in 2010 via the acquisition of Nolato Contour, a TDC was also set up in the US shortly after. In 2020, additional development resources were added via the acquisition of what is now Nolato GW.

Resources on three continents

These resources have now been merged to create a group-wide, global Technical Design Center with resources in Europe, North America and Asia.

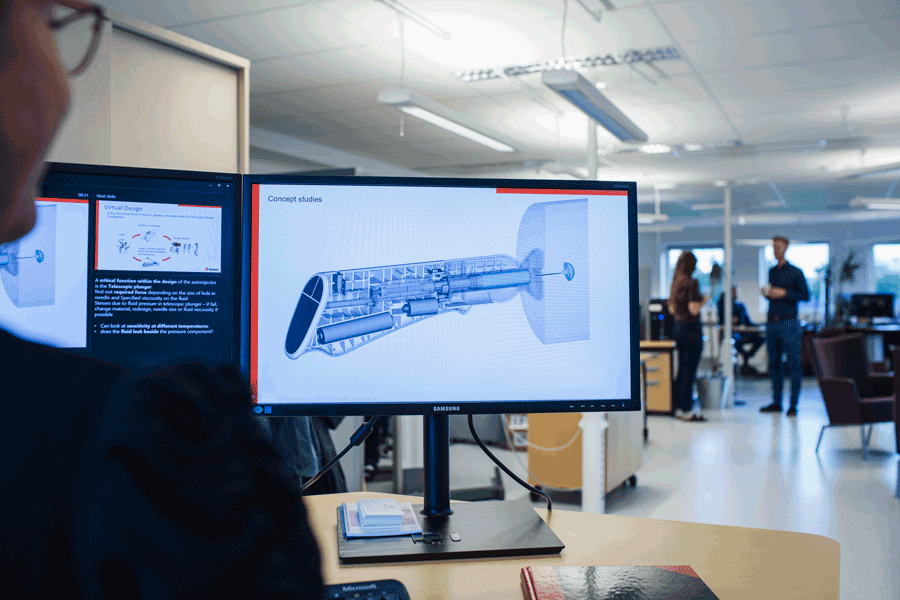

“Our global TDC functions as a hub within Nolato to support customers in the development of new products, from project launch to industrialization. The basic premise is to be experts in areas such as simulation of the prospective design to see how it works in reality, including assembly of modules and system products, as well as the integration of electronics in the products and advanced decorative technologies,” explains Patrik Ingvarsson.

Our mission is to work with our customers using advanced analysis tools to clarify the connection between the product’s function and the design of each individual component, and thus understand the significance of using resources in the right way.

“It’s generally accepted that the cost of a product is determined during the development phase. The same can be said of the product’s environmental footprint: 80% relating to a product’s eco-design is determined at the drawing board stage,” notes Patrik Ingvarsson.

TDC employees therefore also work alongside Nolato’s sales organization to contribute their expertise at the start of a new customer project, particularly if it has not yet been decided which of Nolato’s production units would be best suited to the project.

Knowledge bank

Part of the process also involves TDC engineers working closely with local experts at the production units.

“We recognize the principle behind One Nolato, and also regard TDC as a knowledge bank that harnesses internal networks to keep continually up to date with the experience and expertise that exists among over 200 qualified project engineers at our production units on three continents,” notes Bill Torris, Director TDC North America. “The opportunity to transfer expertise from different customer sectors is a significant part of our customer offering.

“Without close collaboration between TDC and the individual production units, there’s a risk of everything being just theoretical,” stresses Bill Torris. “Nolato’s considerable experience of efficient production, combined with detailed knowledge of the customer’s market, means there is never a gap between theory and practice.

“And that’s something that is of huge benefit to our customers in their projects.”

- Nolato

- Technical Design Center

- Nolato Magasin

You might also be interested in

SERVICES

Nolato offers a wide range of services to support your business

STORIES

Major new solar farm in southern Sweden enters operation

STORIES