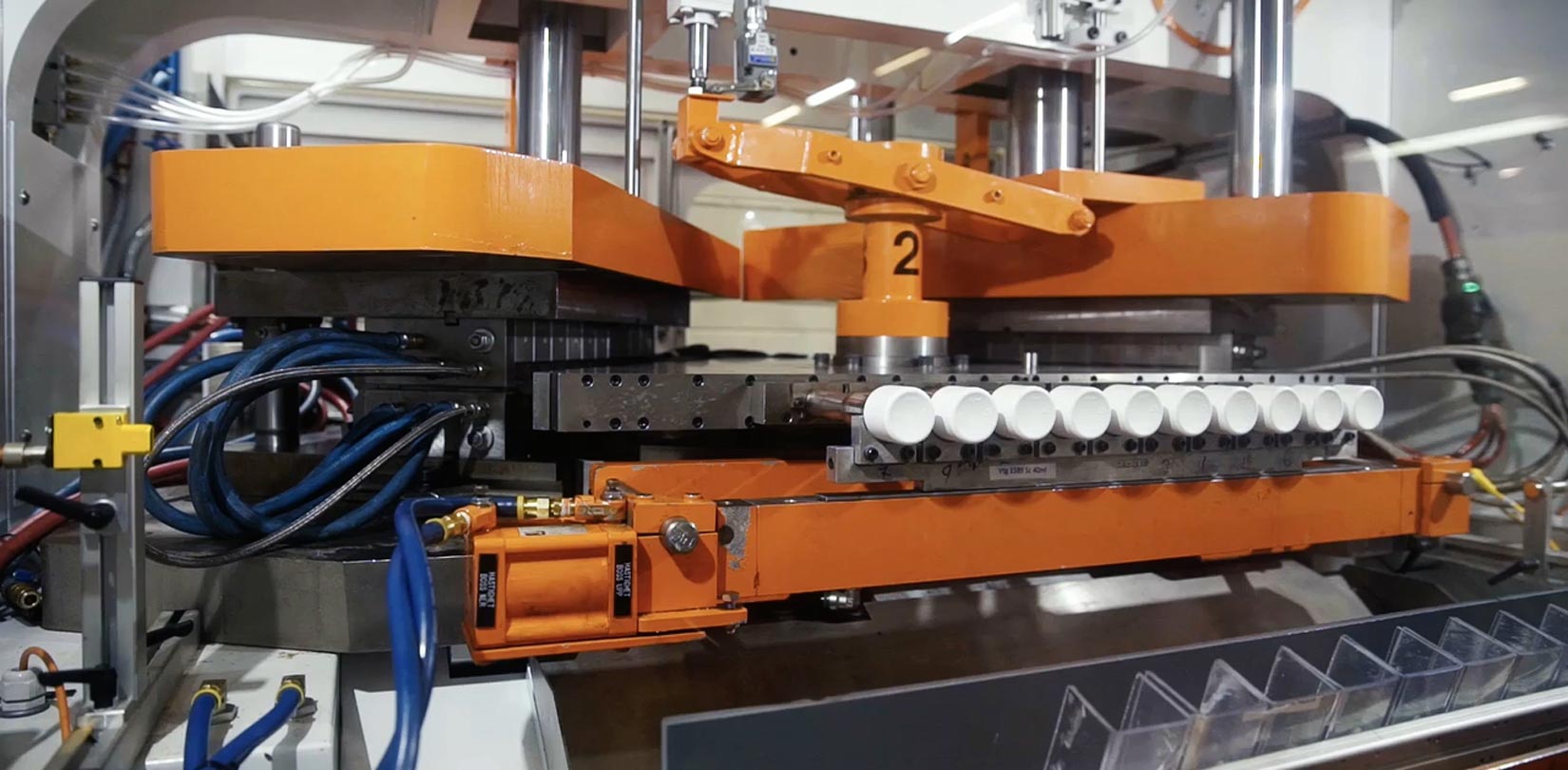

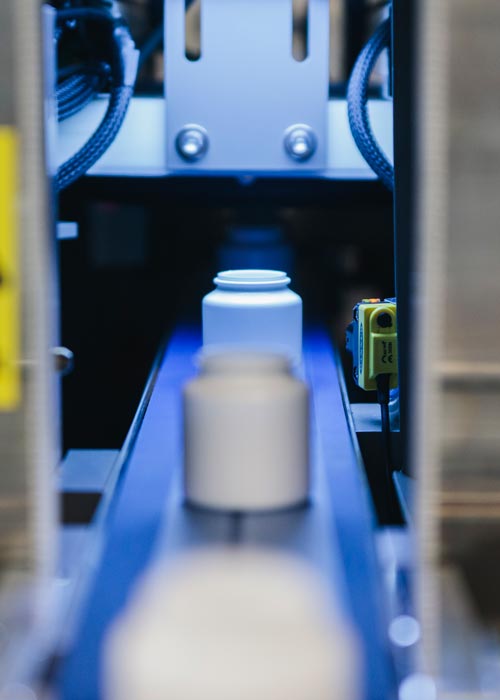

Nolato's extensive experience in injection blow molding (IBM) ensures high precision, smooth finishes and efficient high-volume production offering a wide range of design opportunities.

Creating world-class operations

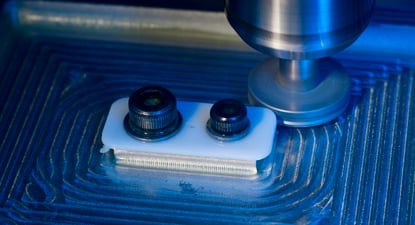

Medical Excellence is our way of creating world class operations inspired by the Nolato spirit, our strategies, quality standards and our lean processes and tools. Together, these elements create a framework for managing resources efficiently and increasing value for our customers.