Avoid production backlogs and improve time-to-market

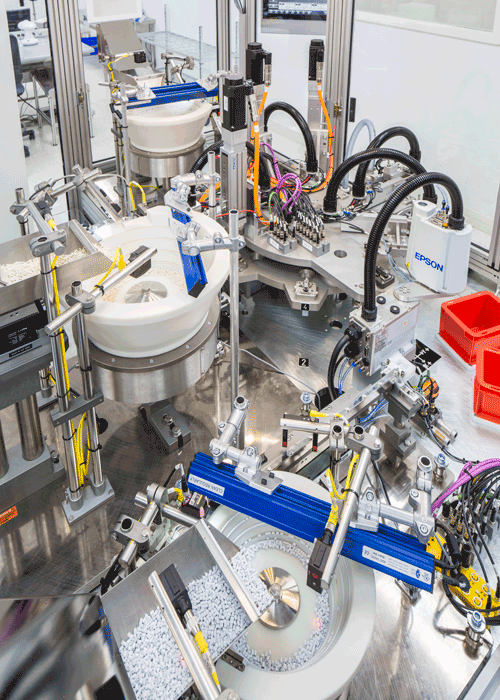

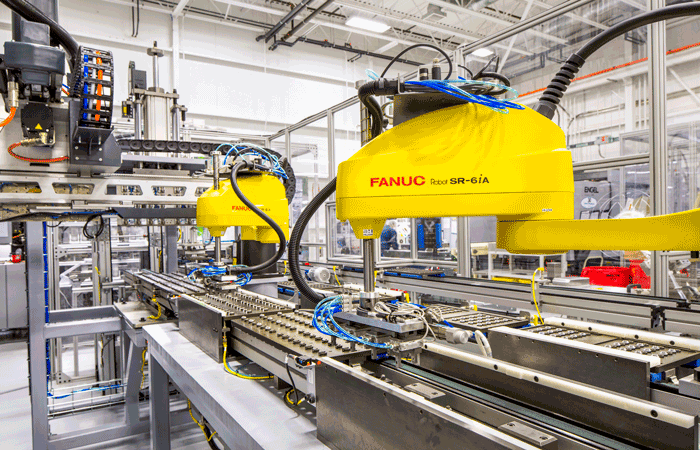

Cut production machine downtime in developmental work with our dedicated facility and a focus on lean manufacturing, using electric molding machines and press-side automation.

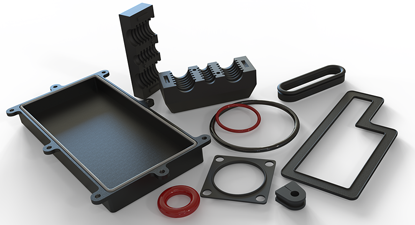

Cutting-edge injection-molding techniques

The key steps involved in scientific injection molding include mechanical cycling, short-shot analyses and fill studies, viscosity curve and gate freezing, balancing of fills between cavities, high/low challenges, weight studies and use of cavity pressure transducers.

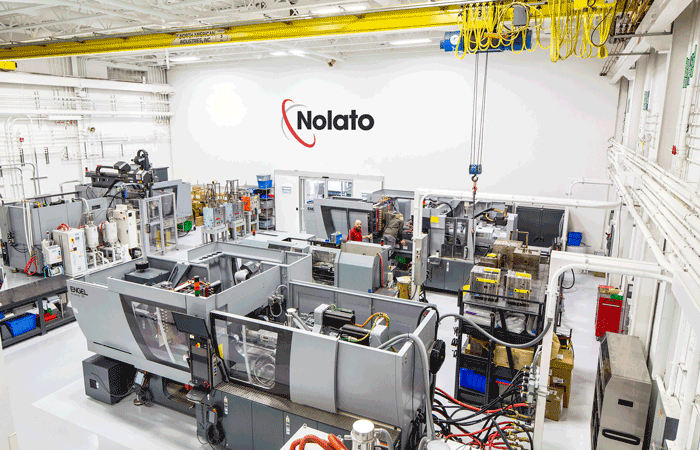

Development of robust processes regardless of manufacturing location

We build entire manufacturing cells in a dedicated non-production facility. These are then delivered to a production plant as a completely automated and validated system.

Ensure high-quality, repeatable production

Scientific injection molding offers consistent product quality, despite expected variations in molding materials and equipment.

Mold-specific rather than machine-specific process development

Our molds are put through scientific process development and validation testing, so that when the molds are sent to a production facility, the process is duplicated rather than developed from scratch.

Proven methodology with rigorous statistical validation

Nolato's systematic approach using the principles of scientific molding, coupled with rigorous statistical validation, ensures a repeatable process for the life of the program.