Nolato utilizes electrically conductive silicone, coupled with extensive expertise and experience, in our electromagnetic interference (EMI) shielding solutions for electromagnetic compatibility (EMC). Our high-performance MIL SPEC EMI shielding products ensure integrity and quality in aerospace, automotive and telecommunication applications.

Contact us

Sending Email...

Contact person/s

Jonas Carlsson

Director Global Sales

+46 708 12 99 95

STANDARD PRODUCT

EMC products

Nolato is dedicated to leading in technology, investing in ongoing development of materials and methods for large-scale production. Some of our shielding products adhere to M83528 standards and various commercial standards, catering to diverse shielding requirements across multiple markets.

Compashield®

Compashield is our proprietary brand of molded and extruded EMI shielding gaskets in the form of cans, frames, tubes, sheets and components.

Trishield®

Trishield, Nolato's unique dispensing technology, has been widely used by leading companies in high-tech industries requiring EMI shielding for over a decade.

MIL SPEC EMI shielding products

Nolato’s MIL SPEC EMI shielding products are manufactured to M83528 standards of the Defense Logistics Agency, as well as a variety of commercial standards to cover a broad spectrum of shielding needs across multiple markets. Standard Mil-Spec products include gaskets, O-rings, sheets, and extrusions.

Comprehensive expertise

Our engineers cooperate closely with our customers to design unique EMI shielding in challenging environments.

Extensive experience

Nolato is at the forefront of EMC engineering and works with global operators in telecom infrastructure and automotive ADAS systems.

Product range

STANDARD PRODUCTS

Compashield®: Advanced EMI Shielding Gaskets for Optimal Protection

Compashield EMI shielding gaskets offer a comprehensive range of molded and extruded solutions tailored for EMI protection.

STANDARD PRODUCTS

Trishield® EMI Shielding FIP Gaskets

High-performance EMI shielding, unique triangular design, low compression, and optimized shaping for reliable electronics.

STANDARD PRODUCTS

EMC shielding products

An extensive range of radio frequency and electromagnetic interference (RF and EMI) screening products such as shielded windows, vents and gaskets that can be completely customized for your needs.

STANDARD PRODUCT

Compashield SMT Grounding Pad

Nolato delivers flexible SMT grounding pads and EMI shielding solutions. Engineered for demanding electronics applications, our products provide reliable electrical performance and durability under mechanical and environmental stress.

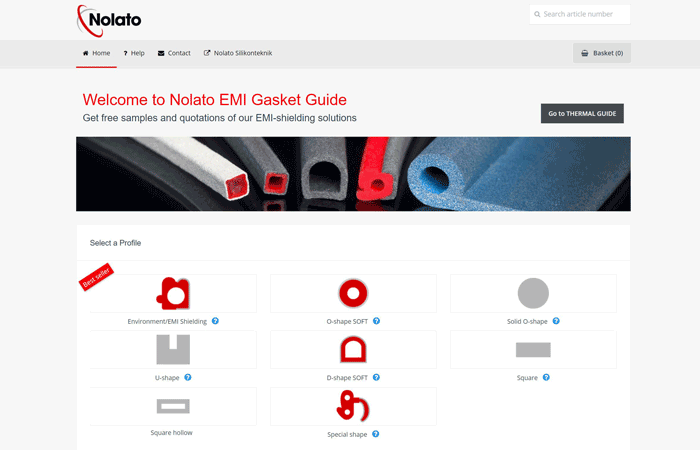

Find the right gasket and order free samples.

Our Guides allows you to find the best EMI solution to meet your requirements. You can also order free samples and obtain a quote.

Continual development

We invest in the continual development of combinations of materials and methods for large-scale production processes.

Demand for EMI solutions is increasing rapidly. Whether you are creating a breakthrough high-tech product or working on very high-volume consumer goods, you understand the importance of cost-effective, reliable EMC solutions to your success. Nolato works with your specifications to find the best solution for your needs.

SELECTION OF markets WE SERVE

INDUSTRY

Automotive

Nolato are a leading provider of electromagnetic interference (EMI) shielding and thermal interface solutions.

INDUSTRY

Telecom

Nolato provides EMI shielding, thermal management, and IP sealing solutions for the telecom industry, ensuring reliable performance in 5G infrastructure, base stations, and routers. Our expertise in customized solutions and high-volume manufacturing makes us a trusted partner for telecom equipment manufacturers.

INDUSTRY

Aerospace

Nolato's electromagnetic interference (EMI) shielding, thermal interface, and silicone sealing and damping products are widely used in the aerospace industry.

Always ready for new directions

Our applications specialists as well as our research and development team are very perceptive and always ready to take turns in new directions. Wonder if we have the solution for you? We probably do.

Looking for a partner for thermal interface material products?

We offer thermal solutions to achieve optimal efficiency and cost savings in electronics cooling.

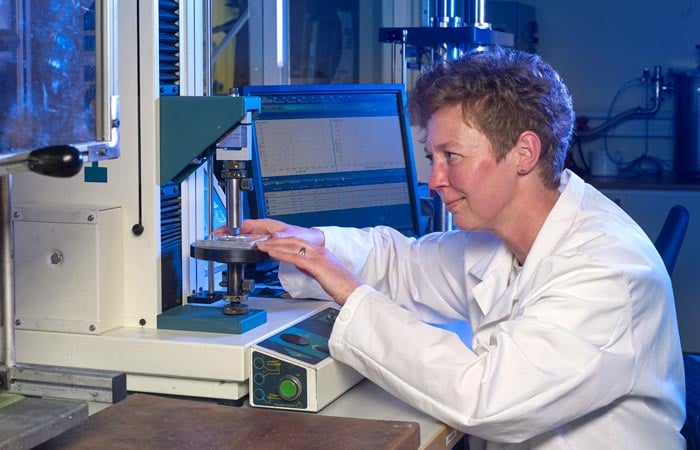

Our EMC facilities

Nolato Silikonteknik's EMC technology and production base is located in Hallsberg, Sweden. We also have production resources under our own management in Beijing and Suzhou, China, Penang, Malaysia, Andover, USA, Mosonmagyarovar, Hungary and Harlow Essex, UK. This is where carry out production and develop the materials and technologies in our Compashield® and Trishield® products.

TECH & RESEARCH

EMC tech center

Our technical center in Hallsberg, Sweden, is where we development advancements in the field of EMC and electromagnetic interference technologies for continual product and production development. It is here that we develop and refine our unique electrically conductive silicone rubber and optimize the most cost-effective production methods.

PRODUCTION AND PARTNERS

Production center and production partners

An EMC production partner is a manufacturer licensed by Nolato to use our materials and technologies for large-scale production, with ongoing support from Nolato Silikonteknik. This support extends all the way from research and development to quality control. Today we have numerous EMC production partners for our Trishield® products and manufacturing around the world, with a primary focus on Asia. We work with a growing number of partners and welcome experienced companies to join us.

You might also be interested in

SERVICE

Thermal interface materials and solutions

Global Thermal Interface Material Solutions for Optimal Heat Transfer: From Development to Delivery.

STANDARD PRODUCT

Thermal Interface Materials

Our thermal interface material (TIM) portfolio and our leading expertise in this field provide you with support and solutions for optimal efficiency and cost savings in electronics cooling. We have the know-how and resources to guide you throughout the thermal interface material process.

SERVICE

EMI shielding

Advanced EMI shielding solutions with MIL spec compliance. Nolato offers Trishield dispensable EMI gaskets and Compashield conductive gaskets, ensuring optimal electromagnetic compatibility.