High precision and quality

We ensure outstanding precision through advanced engineering, tightly controlled manufacturing processes, and modern production technologies. Each component is produced to exacting specifications, supported by rigorous validation and in-line quality control. Our strong focus on repeatability, process stability and regulatory compliance guarantees reliable performance for even the most demanding applications.

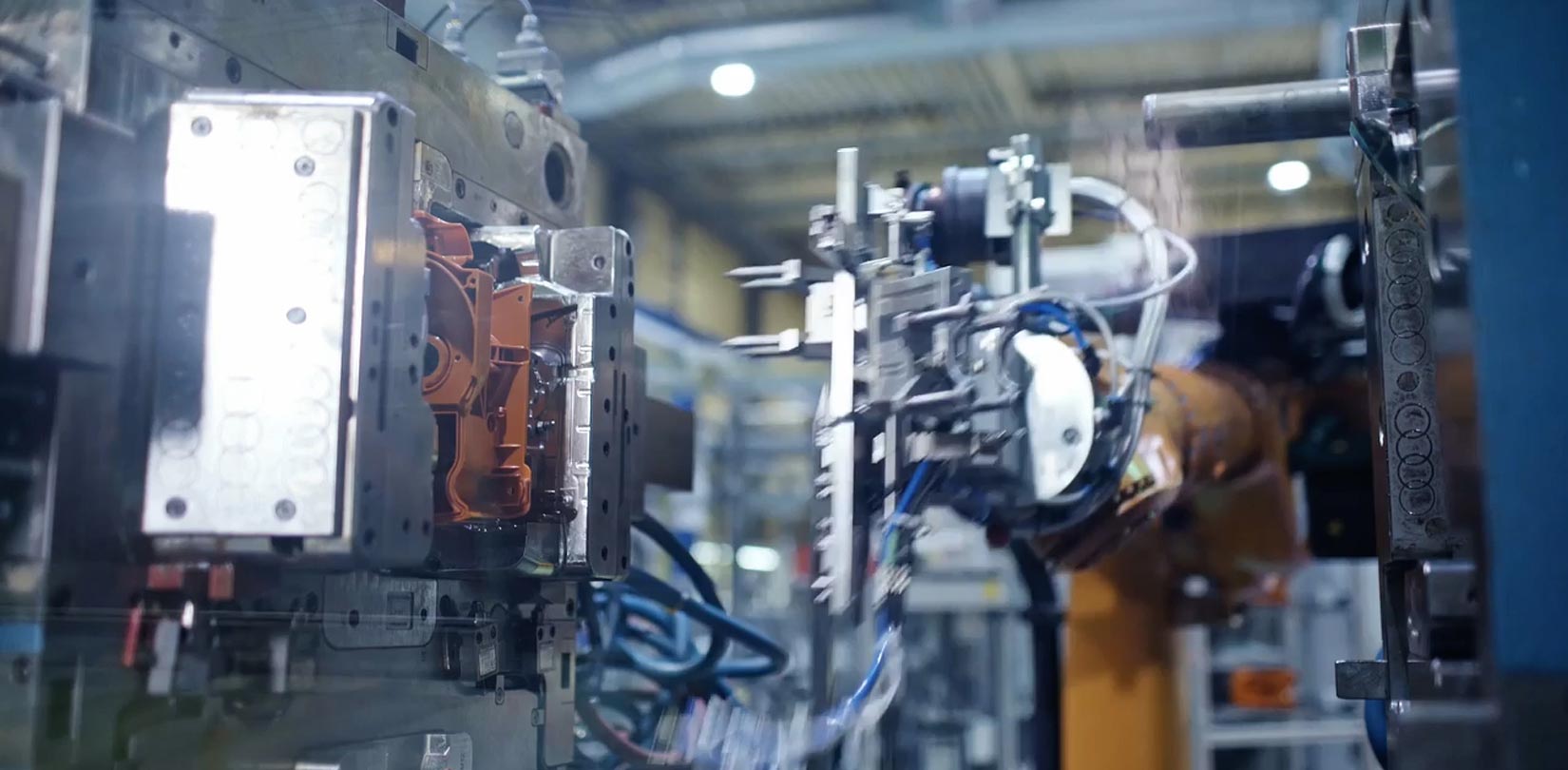

Injection molding 1K

We offer advanced single-component (1K) injection molding solutions for both thermoplastics and liquid silicone rubber. This technology is ideally suited for high-volume production of precise, single-material parts across a wide range of industries. Automated workflows, modern equipment and stringent quality controls ensure cost-efficiency, consistency and short cycle times.

Injection molding 2K to 4K

We specialize in multi-component (2K to 4K) injection molding, enabling the integration of multiple materials or colors into a single part. This capability allows for enhanced functionality and design flexibility, reducing assembly steps and improving product performance.

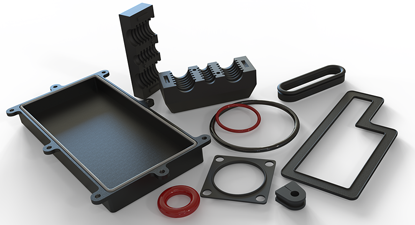

Micro to Macro

Our injection molding capabilities span from ultra-small components weighing less than 0.05 grams to large, structurally demanding parts produced on machines with clamping forces up to 3’200 tons. This wide range enables us to support diverse product dimensions, from microfluidic features to large-scale system components. Whether for high-precision micro or robust macro parts, we deliver scalable solutions according to our customer’s needs.