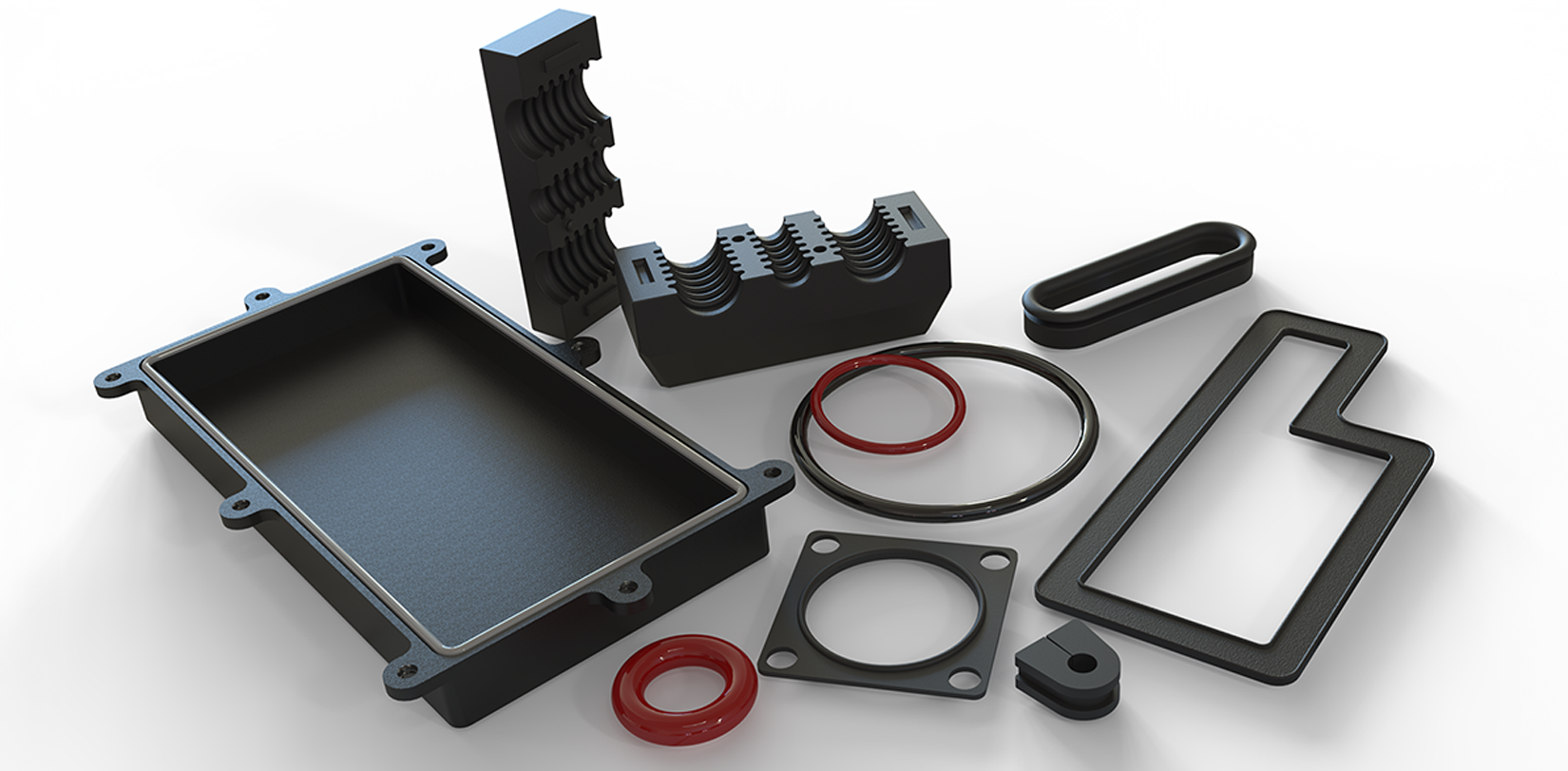

Nolato delivers IP sealing solutions, engineered to meet the toughest IP demands. Our gaskets, molded, extruded, or dispensed, ensure superior environmental protection.

Geometry-Driven EMI Shielding – Advanced FIP Gasket Design

Technical white paper on geometry-driven FIP EMI gaskets, explaining how gasket geometry impacts shielding effectiveness, assembly force, material usage, and manufacturability in compact electronic enclosures.