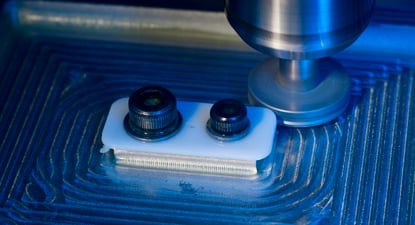

Additive manufacturing for conformal cooling

We offer steel 3D printing for conformal cooling to improve cycle times – in some cases by up to 30% – as well as improving component quality and enabling design flexibility. This technology streamlines tool design, reducing the components needed to build a mold.

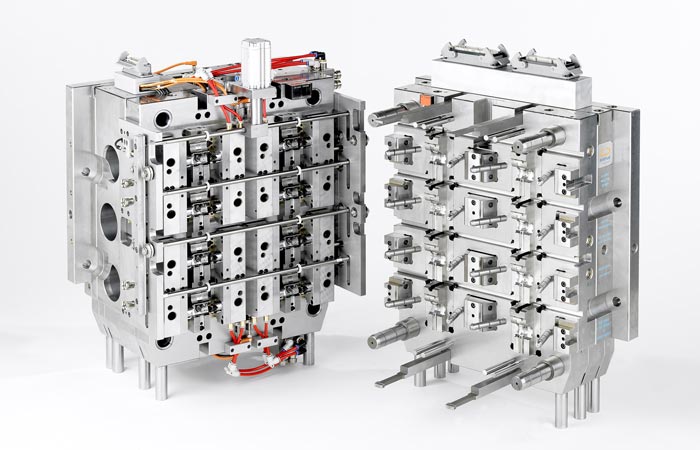

Advanced molds for a range of unique products

We are experienced in tooling for 2K/3K molding, automated insert molding, IMD and IML and specialize in custom tooling for many product types, including medical/pharmaceutical devices, handheld consumer electronics, home security, audio, telecoms, automotive and many more.

Robust mold validation and optimization

We have significant expertise in IQ, OQ and PQ validations for Class 7 and 8 cleanrooms, and offer a full suite of mold optimizations including installation support, validations at customer locations, mold modification assistance and customer training.

Global tooling for diverse materials

We support complex tooling with the global capacity to handle large-scale programs, including ultra-high cavitation and multi-component applications. Nolato also offers mold design-and-build for both thermoplastic, liquid silicone rubber (LSR), ceramic and metal stamping products.

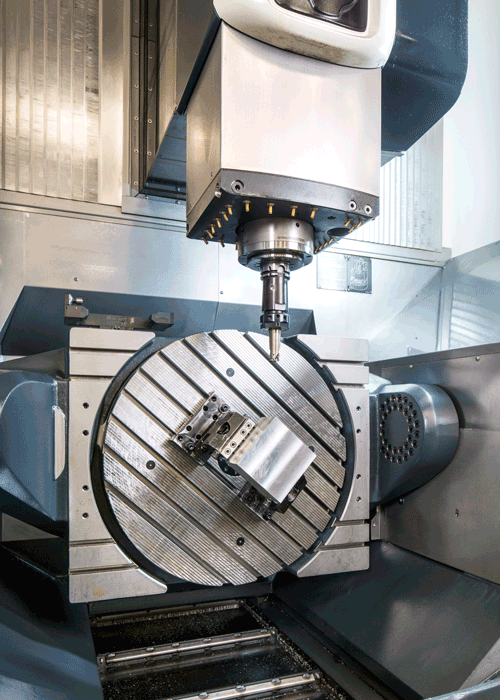

Precision machining

To support our mold-making capabilities, we offer a wide range of machining options with state-of-the-art equipment, including high-speed/multi-axis CNC mills and automation for maximum accuracy and speed.