Our thermal interface material (TIM) portfolio and our leading expertise in this field provide you with support and solutions for optimal efficiency and cost savings in electronics cooling. We have the know-how and resources to guide you throughout the thermal interface material process.

Contact us

Sending Email...

Contact person/s

Jonas Carlsson

Director Global Sales

STANDARD PRODUCT

Thermal Interface Materials

Compatherm®

Customization

Comprehensive expertise

Extensive experience

What are Thermal Interface Materials?

Thermal Interface Material (TIM) is essential for electronics cooling, serving to improve thermal conduction between surfaces by filling air gaps and surface irregularities. This reduces thermal resistance and enhances heat dissipation from electronic components to cooling devices.

Available in various materials like metals, ceramics, and silicone thermal interface materials, TIMs are tailored to meet diverse application needs. Our portfolio, combined with our expertise, offers efficient, cost-effective thermal management solutions.

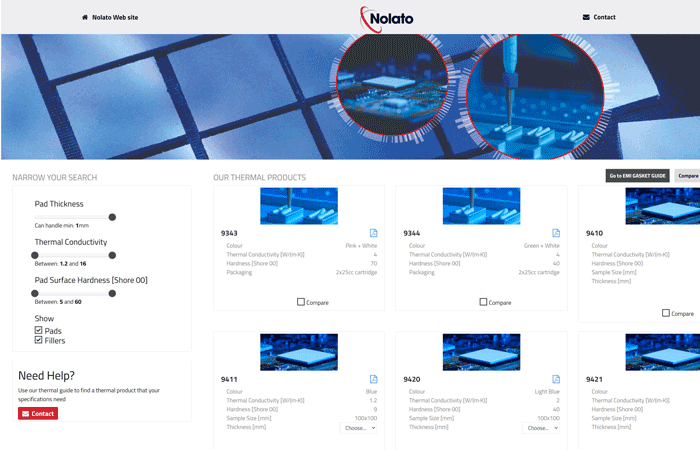

Product Range of Thermal Interface Materials

STANDARD PRODUCT

Compatherm Pad® : Thermal Heating Pads

STANDARD PRODUCT

Compatherm®: Thermal Gap Filler

STANDARD PRODUCT

Compatherm® Thermal Paste

Take a look inside our Thermal Guide

Application areas for TIM Materials

SELECTION OF INDUSTRIES WE SERVE

INDUSTRY

Automotive

INDUSTRY

Telecom

INDUSTRY

Aerospace

Always ready to explore new areas

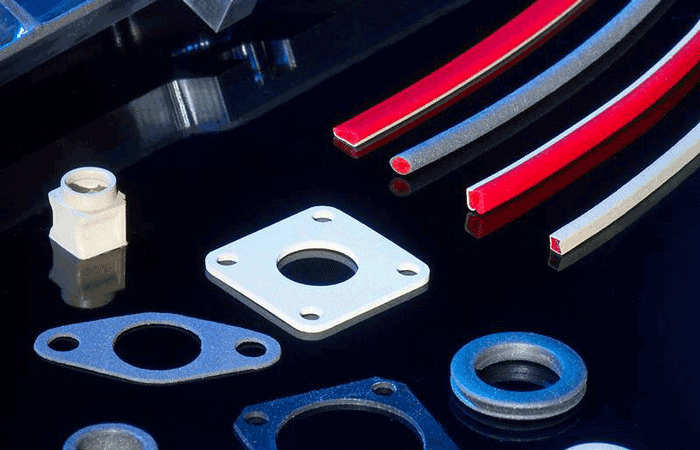

Looking for an EMC product partner?

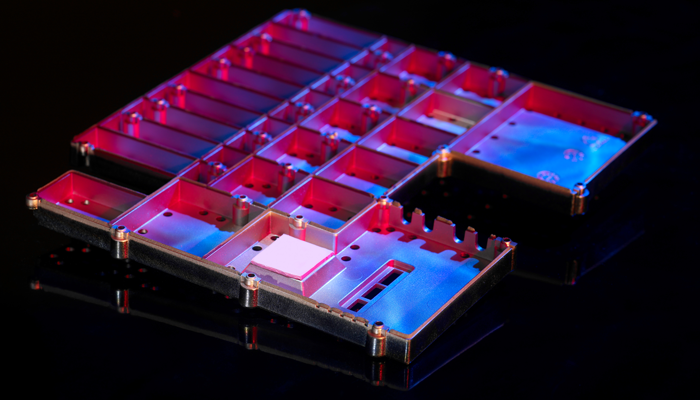

Our thermal management facilities

TECH & RESEARCH

Thermal management tech center

PRODUCTION

Production center and production partners

Our main production centers have their own management organizations in Beijing, China, and Penang, Malaysia. These centers house the production, materials and technologies included in our Compatherm product category.

A thermal management production partner is a manufacturer licensed by Nolato to use our materials and technologies for large-scale production, with ongoing support from Nolato Silikonteknik in Hallsberg, Sweden.

Helpful resources

White papers

Whitepaper

How different Thermal interface material enhance

Whitepaper

How thermal management affects your product and business

Companies offering Thermal Interface Material products

GROUP COMPANY

Nolato Silikonteknik

You might also be interested in

INDUSTRY

Automotive

INDUSTRY

Telecom

STORIES