Discover advanced heat management with our dispensable thermal filler, tailored for easy integration in complex electronics and high-volume production.

Contact us

Sending Email...

Contact person/s

Jonas Carlsson

Director Global Sales

+46 708 12 99 95

STANDARD PRODUCT

Compatherm®: Thermal Gap Filler

Our Thermal gap filler enhances thermal conductivity and heat dissipation, ensuring device reliability and performance, making it ideal for a variety of applications.

Compatherm® Filler

Advanced Thermal Conductive Gap Filler for Heat Management

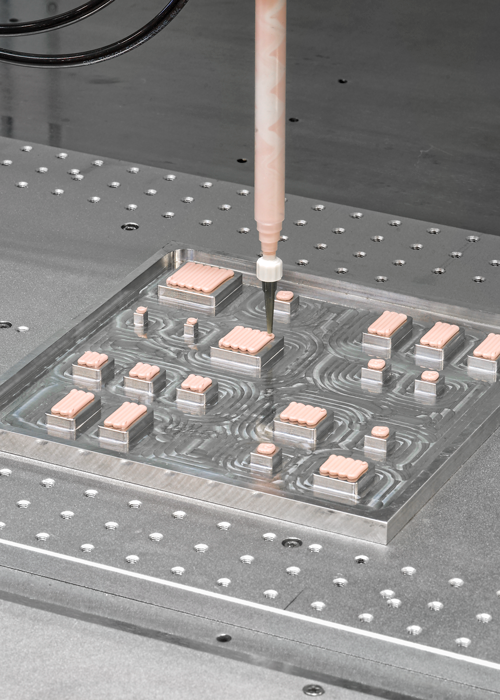

Our thermal gap filler is made using high-quality materials and developed to meet a growing need for reliable, cost-effective thermal solutions in high-tech industrial applications. Compatherm thermal filler is a liquid-dispensed thermal filler that can seamlessly conform to any arbitrary geometry and provide negligible component strain while being highly adaptable to high-volume production.

Advantages of Compatherm® Thermal Gap Filler

Optimal heat management

Combines thermal conductivity and low thermal resistance to ensure efficient heat dissipation, maintaining ideal operating temperatures for electronic components.

Adaptable application of thermal fillers

Features high conformability and minimal component stress, easily filling gaps of any shape at low pressure to facilitate perfect thermal contact without damaging sensitive parts.

Precision and efficiency

Offers precision tolerance compensation and supports seamless integration with automated dispensing systems, ensuring consistent thermal performance and efficient, large-scale application.

Cost-effective for high volume

Provides an economical solution for high-volume applications, allowing for the cost-effective deployment of thermal gap fillers without compromising quality.

Customized thermal solutions

Delivers customizable solutions, tailored to meet unique thermal management challenges across a variety of applications, ensuring optimal fit and performance.

Matrix and downloads

compatherm® 1P Filler Material matrix

| Test standard | Unit | 9230 | 9263 | |

| Base matrix | Silicone 1-part | Silicone 1-part | ||

| Thermally conductive filler | Ceramic | Ceramic | ||

| Color | Visual | White | Pink | |

| Cure time @25°C | h | n/a | n/a | |

| Thermal Conductivity | ISO 22007-2 mod | W/(m-K) | 3.70 | 6.00 |

| Viscosity | 10s-1 | Pa·s | 380.00 | 630.00 |

| Flowrate | 3.2mm nozzle @ 90 PSI | g/min | 36 | 39 |

| Density | ASTM D792 | g/cm3 | 3.23 | 3.3 |

| Outgassing, TML | ASTM E595 Modified | % | 0.1 | 0.1 |

| Dielectric Breakdown Voltage | ASTM D149 | VAC/mm | 8 000 | 6 000 |

| Operating Temperature | ˚C | 40 to +150˚C | 40 to +150˚C | |

| BLT (Bond Line Thickness) | mm | 0.09 | 0.22 | |

| Shelf life | months | 6 | 6 |

compatherm® 1P Filler Material matrix

| Test standard | Unit | 9290 | 9291 | 92100 | 92120 | |

| Base matrix | Silicone 1-part | Silicone 1-part | Silicone 1-part | Silicone 1-part | ||

| Thermally conductive filler | Ceramic | Ceramic | Ceramic | Ceramic | ||

| Color | Visual | Purple | Greyish Green | Purple | Purple | |

| Cure time @25°C | h | n/a | n/a | n/a | n/a | |

| Thermal Conductivity | ISO 22007-2 mod | W/(m-K) | 9.00 | 9.00 | 10.00 | 12.00 |

| Viscosity @ 10s-1 | Plate-plate rheometer | Pa·s | 750.00 | 510.00 | 500.00 | 400.00 |

| Flow Rate | 3.8mm nozzle @ 90 PSI | g/min | 30 | 30 | 30 | 30 |

| Density | ASTM D792 | g/cm3 | 3.10 | 2.95 | 3.03 | 3.10 |

| Outgassing, TML | ASTM E595 Modified | % | 0.08 | 0.1 | 0.06 | 0.05 |

| Dielectric Breakdown Voltage | ASTM D149 | VAC/mm | 6 000 | 6 000 | 6 000 | > 10 000 |

| Operating Temperature | ˚C | 40 to +150˚C | 40 to +150˚C | 40 to +150˚C | 40 to +150˚C | |

| BLT (Bond Line Thickness) | mm | 0.25 | 0.17 | 0.25 | 0.25 | |

| Shelf life | months | 6 | 9 | 6 | 6 |

compatherm® 2P Filler Material matrix

| Test standard | Unit | 9321 | 9323 | 9330 | 9344 | |

| Base matrix | Silicone 2-part | Silicone 2-part | Silicone 2-part | Silicone 2-part | ||

| Thermally conductive filler | Ceramic | Ceramic | Ceramic | Ceramic | ||

| Color, part A | Visual | White | White | White | White | |

| Color, part B | Visual | Yellow | Yellow | Blue | Green/Pink | |

| Pot life at 25°C | h | 2 | 2 | 2 | 2.5 | |

| Cure time @25°C | h | 18 | 8 | 24 | 12 | |

| Thermal Conductivity | ISO 22007-2 mod | W/(m·K) | 2 | 2 | 3 | 4 |

| Viscosity (mixed) | Brookfield 10rpm | Pa·s | 380 | 250 | 276 | 300 |

| Flowrate | 2mm nozzle at 50 PS | g/min | 40 | 42 | 60 | 36 |

| Hardness | ASTM D2240 | Shore 00 | 55 | 50 | 44 | 50 |

| Density | ASTM D792 | g/cm3 | 2.90 | 2.05 | 2.84 | 3.10 |

| Volume Resistivity | ASTM D257 | Ω∙cm | 2.05x1013 | 7.41x1012 | 2.23x1012 | 2.16x1014 |

| Dielectric Breakdown Voltage | ASTM D149 | VAC/mm | 7 000 | 9 900 | 10 000 | 8 000 |

| Dielectric Constant at 1MHZ |

ASTM D150 | 16.92 | 4.53 | 6.2 | 8.31 | |

| Operating Temperature | ˚C | -40 to +200˚C | -40 to +150˚C | -40 to +150˚C | -40 to +200˚C | |

| Outgassing, TML | ASTM E595 Modified | % | 0.14 | 0.10 | 0.39 | 0.1 |

| Flammability | UL94 (file:E483565) | V-0 | ||||

| BLT (Bond Line Thickness) | mm | 0.095 | 0.11 | 0.08 | 0.25 | |

| Shelf life | months | 9 | 6 | 6 | 6 |

compatherm® 2P Filler Material matrix

| Test standard | Unit | 9361 | 9370 | 9390 | |

| Base matrix | Silicone 2-part | Silicone 2-part | Silicone 2-part | ||

| Thermally conductive filler | Ceramic | Aluminium | Ceramic | ||

| Color, part A | Visual | White | Grey | White | |

| Color, part B | Visual | Green | Grey | Blue | |

| Pot life at 25°C | h | 2 | 2.5 | 3 | |

| Cure time @25°C | h | 15 | 24 | 16 | |

| Thermal Conductivity | ISO 22007-2 mod | W/(m·K) | 6 | 7 | 9.3 |

| Viscosity (mixed) | 10s-1 | Pa·s | 240 | 233 | 270 |

| Flowrate | 2mm nozzle at 50 PS | g/min | 40 | 18 | 30 |

| Hardness | ASTM D2240 | Shore 00 | 55 | 50 | 55 |

| Density | ASTM D792 | g/cm3 | 3.15 | 2.34 | 2.95 |

| Volume Resistivity | ASTM D257 | Ω∙cm | 1.19x1011 | 3.83x1012 | 7.11x1010 |

| Dielectric Breakdown Voltage | ASTM D149 | VAC/mm | 8 000 | 1 337 | 10 000 |

| Dielectric Constant at 1MHZ |

ASTM D150 | 5.64 | 187 | 10 | |

| Operating Temperature | ˚C | -40 to +200˚C | -40 to +150˚C | -40 to +150˚C | |

| Outgassing, TML | ASTM E595 Modified | % | 0.22 | 0.05 | 0.35 |

| Flammability | UL94 (file:E483565) | ||||

| BLT (Bond Line Thickness) | mm | 0.21 | 0.18 | 0.25 | |

| Shelf life | months | 9 | 6 | 9 |

compatherm® POTTING Material matrix

| Test standard | Unit | 9110 | |

| Base matrix | Silicone 2-part | ||

| Thermally conductive filler | Ceramic | ||

| Color, part A | Visual | White | |

| Color, part B | Visual | Pink | |

| Pot life at 25oC | h | 1 | |

| Cure time @25°C | h | 24 | |

| Thermal Conductivity | ISO 22007-2 mod | W/(m-K) | 1 |

| Viscosity (mixed) | 10s-1 | Pa·s | A:15/B:15 |

| Flow Rate | 2mm nozzle @ 50 PSI | g/min | TBD |

| Hardness | ASTM D2240 | Shore 00 | 20 |

| Density | ASTM D792 | g/cm3 | 1.77 |

| Volume Resistivity | ASTM D257 | Ω∙cm | 1.42x1013 |

| Dielectric Breakdown Voltage | ASTM D149 | VAC/mm | 7 000 |

| Dielectric Constant at 1MHZ | ASTM D150 | 4.75 | |

| Operating Temperature | ˚C | -40 to +150˚C | |

| Outgassing, TML | ASTM E595 Modified | % | 0.6 |

| Flammability | UL94 (file:E483565) | ||

| BLT (Bond Line Thickness) | mm | 0.11 | |

| Shelf life | months | 8 |

You might also be interested in

STORIES

EMC and thermal management in automotive

The vehicles become connected and more and more digitalized and electrified. All the waste heat created in PCB housings creates an ever increasing demand for efficient thermal management.

STANDARD PRODUCT

Compatherm® Thermal Paste

Compatherm Paste creates the thinnest possible film between the heat source and heat sink to provide minimal thermal resistance. Compatherm Paste allows a bond line thickness of as little as a few tenths of a micron.

STORIES

Connected vehicles pose data transmission security challenges

Our Form-In-Place EMC dispensing technology and Compashield SMT Pad provide industry-leading grounding and shielding, delivering reliable performance under mechanical and environmental stress.