Located in Shenzhen, China, Nolato Converting offers cutting-edge technology and a highly skilled team that provides precise, efficient, and reliable die-cutting solutions to drive product innovation and market competitiveness.

Contact us

Sending Email...

GROUP COMPANY

Nolato Converting

Nolato Converting is a solutions provider for small-sized precision mechanic, cosmetic and functional parts for leading customers within consumer electronics. In addition to advanced die-cut converting parts, we also offer premium injection-molded ceramic parts, and molded combinations of plastics and ceramics.

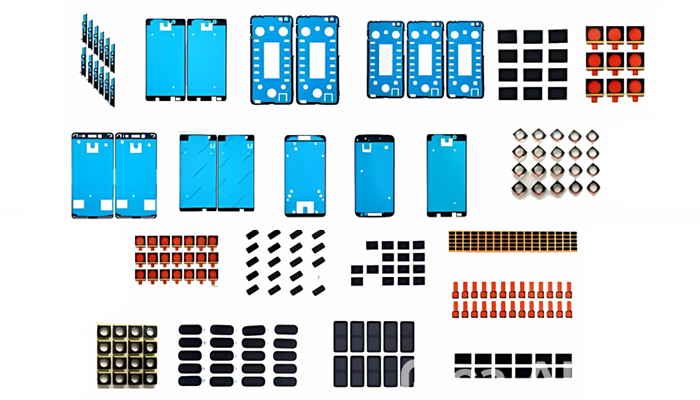

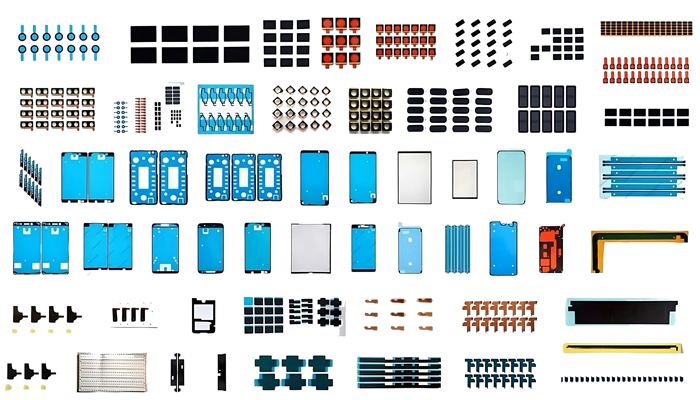

examples of products

- Ceramic mechanical parts

- Die-cut converting parts

- Laser-Activated Adhesive LAA Bonding

- Small-size functional ME parts

- Smart wearable

Converting technology overview

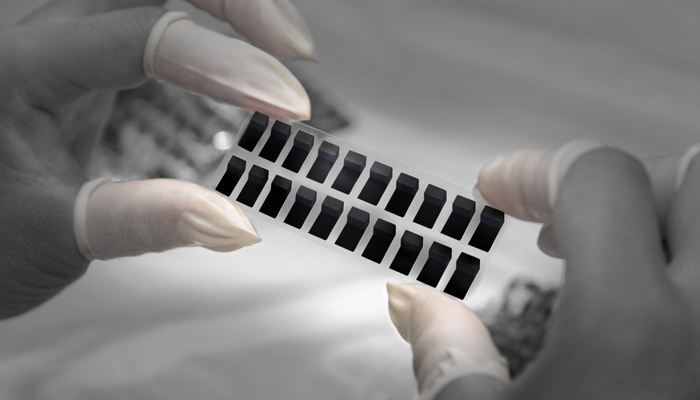

Die-cutting is a precision processing technique that uses specialized molds to accurately cut materials into specific shapes and sizes. It is widely applied across various industries, offering highly customized solutions for diverse applications.

Technical services and support

We provide end-to-end technical support from product concept to mass production:

- Requirement Analysis: Understanding product applications to ensure precise die-cutting solutions.

- Feasibility Assessment: Identifying technical feasibility and optimizing designs for perfect component integration.

- Advanced Die-Cutting Design: Leveraging industry expertise to enhance performance and efficiency.

- Comprehensive Support: Covering process planning, material selection, mold design, and after-sales assistance.

Rapid prototyping

We offer fast, high-precision prototyping to accelerate product validation and optimization, ensuring quick design adjustments based on customer feedback.

High-precision flatbed converting

Flatbed die-cutting provides ultra-high dimensional accuracy (±0.05mm), ensuring consistency and stability for complex shapes. Our proprietary nesting die-cutting enhances precision and material utilization.

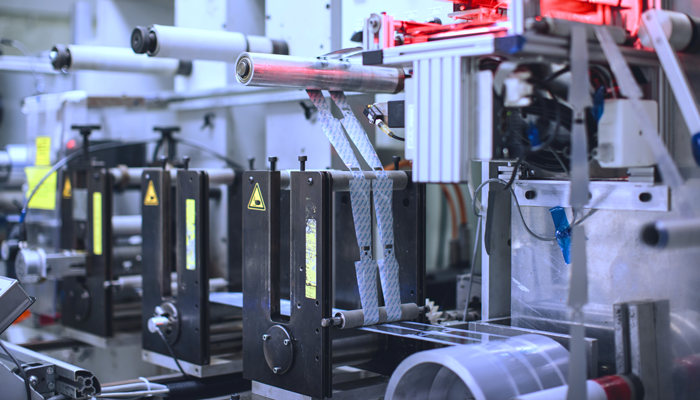

High-capacity rotary converting

Rotary die-cutting is ideal for high-volume production, processing hundreds of meters per minute while maintaining precision (±0.1mm). The satellite-type rotary system achieves tolerances of ±0.05mm, enabling stable mass production of narrow-edge designs (minimum width 0.4mm).

High-performance membrane converting and modules

- Waterproof & Breathable Membranes: Protects electronics from water, dust, and pressure fluctuations.

- Acoustic Membranes: Enhances sound quality while preventing dust and moisture interference.

- Advanced Lamination & Cutting: Ensures uniform membrane tension and flawless integration.

Multi-material lamination

Using advanced layering techniques, we ensure bubble-free, wrinkle-free, and precisely aligned multi-layer composites for die-cutting applications. We support both cold and heated lamination.

Integrated die-cut and plastic component modules

By utilizing ultrasonic welding and thermal pressing, we integrate die-cut components with plastic structures, reducing assembly steps and costs while enhancing functionality.

Laser-Activated Adhesive (LAA) Bonding

LAA is a thermoplastic elastomer with both pressure-sensitive and thermoplastic properties. It provides:

- Superior bonding strength

- Excellent waterproofing and impact resistance

- Rework convenience & ultra-slim bezel capability LAA bonding is widely used in smartphones, wearables, tablets, TVs, and other consumer electronics

Key technical innovations

- Hot-Press Lamination: Enhances adhesion and sealing performance.

- Automated Die-Cut Placement: Improves accuracy, quality, and efficiency.

- Inline AOI Hole Inspection: Enables real-time defect detection and quality assurance.

- Bidirectional Stretch Lamination: Ensures precise stretching of functional films (EPTFE) for enhanced performance.

Common die-cutting materials and applications

- Double-Sided Tape: Fixing electronic components and packaging.

- Polyurethane Foam: Cushioning and sealing for mobile and computing devices.

- Conductive Foam: EMI shielding for electronic components.

- Copper & Aluminum Foil: Conductivity and shielding applications.

- Thermal Management Materials: Graphite sheets, thermal gel, and metal-based heat dissipation solutions.

- Waterproof Acoustic Membranes: Used in earpieces, speakers, and microphones for sound transmission and environmental protection.

- Nylon Mesh: Used in speaker grilles and electronic enclosures.

- Laser Adhesive: Advanced bonding solutions for ultra-thin electronic components.

Our site

Our site offer a production of advanced converting components in both standard and cleanroom environments.

Contacts

If you would like to find out more about Nolato Converting's services and products, please contact one of our team members or use the form at the bottom of this page.

Stella Chuang

Business Development Greater China Area

TJ Tan

Business Development South East Asia

Nam Wei Liew

Business Development Director Asia

Want to know more?

Read more about our ceramic solutions and services

CAREERS AT NOLATO

Join our team

The Nolato Group consists of three business areas that develop and manufacture products in polymer materials such as plastics, silicone and TPE. The Nolato Group offers stimulating roles and good development opportunities in an international work environment.

Explore careers in China

Explore careers in China

Stories

STORIES

Nolato Sustainable Procurement initiative 2024

Together with our suppliers we can significantly reduce our carbon footprint and enhance our sustainability performance.

STORIES

Shrinking our carbon footprint

Nolato is cutting its global carbon emissions by purchasing renewable electricity in China, taking an important step towards the target of reducing its carbon footprint by 80% by 2025.

STORIES

R-thinking key to developing new products

At Nolato, we believe in rethinking how products are designed to support a sustainable future. By adopting R-strategies—such as reuse, repair, and recycling—we aim to minimize resource use and reduce waste.

Would you like us to contact you instead?

Please fill in the form and select your preferred method of contact and we will get back to you as soon as possible.

You might also be interested in

SERVICE

Ceramic injection molding

Our service includes the development of alumina and zirconia ceramic compound for injection molding and product line customization, suitable for large-scale production.

SHARE INFORMATION

Trading history

Overview of the trading history of Nolato’s share.

Quality control and hygiene standards

Our policy is to always meet our customers′ requirements and expectations. The fact that our production takes place in a clean environment (hygiene and clean rooms up to class 7), and that we were among the first companies in Europe to be certified in accordance with ISO 15378 is proof of our commitment to always deliver the right quality.