LSR applications for critical components

LSR (Liquid Silicone Rubber) is widely used in critical applications where failure is not an option. We specialize in tight-tolerance LSR injection molding, delivering shot-to-shot repeatability and reliable, high-volume production for demanding industries.

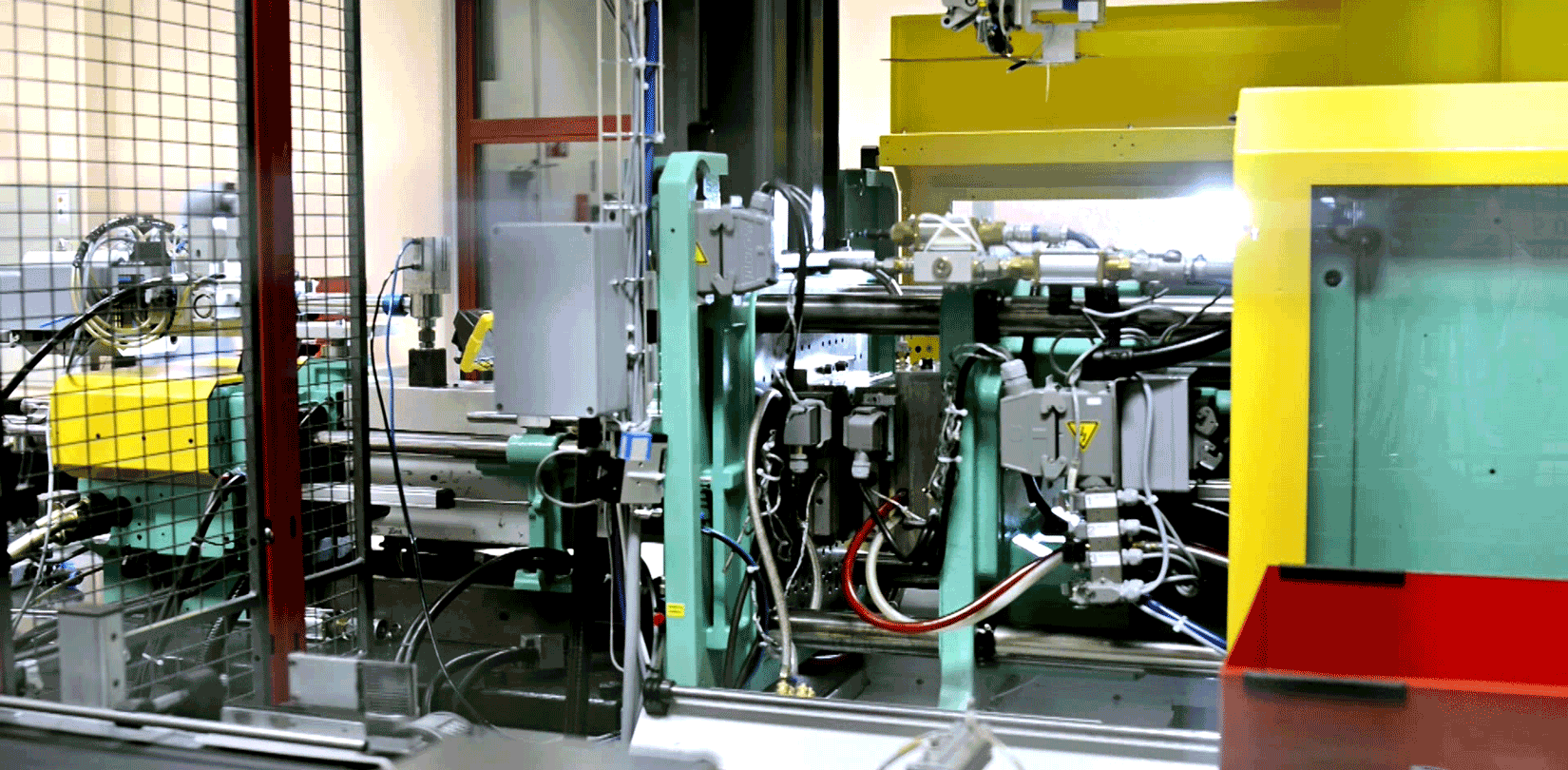

Automatic silicone molding

Our fully automated LSR injection molding ensures consistent cycle times, reduces manual handling, and improves production efficiency while maintaining exceptional quality standards and repeatability.

Liquid Silicone Rubber (LSR) design flexibility

Liquid Silicone Rubber enables:

- Tighter tolerances compared to thermoplastic elastomers

- Anti-allergenic and biocompatible material performance

- Precision features and complex geometries

- Consistent wall thickness and reduced sink

- Undercuts and negative drafts without secondary processing

Biocompatibility and performance properties

LSR is ideal for medical and healthcare applications, including short- and long-term implants, due to its:

- Bacterial resistance

- Sterilization compatibility

- Odorless, tasteless, and stain-resistant properties

Durable and sustainable LSR solutions

Silicone is highly resistant to environmental factors, ensuring long-lasting product durability:

- UV, heat, and moisture resistance

- No discoloration or loss of transparency over time

- Scratch, crack, and break resistance

Multi-material LSR molding

We specialize in multi-material molding solutions, including:

- Two-shot molding

- Insert molding

- Overmolding

These techniques expand product performance possibilities by enabling integrated silicone-plastic and silicone-metal solutions — often eliminating secondary assembly steps.