Mass balance for plastic is a useful way of slowly introducing renewable raw materials by mixing them with fossil raw materials to gradually phase them out of a product

Contact us

Sending Email...

FOCUS ON SUSTAINABILITY

Mass balance cuts carbon footprint

Wellspect HealthCare has started use mass balance in the production of a urine catheter, which has cut the plastic’s carbon footprint by 55%.

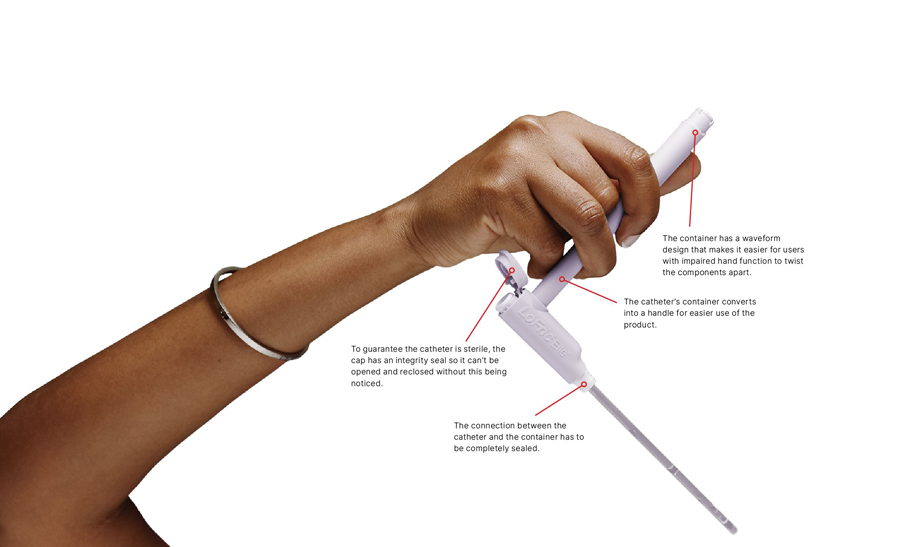

Global medtech firm Wellspect HealthCare, headquartered in Mölndal outside Gothenburg, has now begun using mass balance as a method of gradually replacing fossil raw materials with bio-based circular raw materials in a urine catheter made by Nolato and sold under the name LoFric Elle (see article in Nolato Magasin no 32).

Mass balance is starting to be used in the production of LoFric Elle to gradually replace fossil materials with bio-based circular raw materials.

Game-changer for medtech

The mass balance method makes it possible to trace the amount of bio-based circular raw material entering the value chain and attribute it to a product that is leaving the value chain. Compliance is verified by ISCC (International Sustainability and Carbon Certification), and both the manufacturer and the customer are certified or licensed.

“Identifying more sustainable raw material sources to produce medical plastic products is a game-changer for manufacturers of medical devices,” explains Svenn Poulsen, Group Vice President at Wellspect Healthcare. “By replacing fossil raw materials with bio-based ones, we reduce the carbon footprint of the end product without affecting the product’s clinical performance.”

Safeguarding quality

The original LoFric Elle catheter, launched in 2019, was made using solely conventional fossil-based raw material sources. Now mass balance is being used as a method of transitioning to bio-based circular raw materials, while guaranteeing the same medical quality as before.

According to Wellspect, the mass balance method reduces the carbon footprint of plastic in the product by 55% compared with the original product.

“In short, mass balance means we order the necessary amount of bioplastic from one of our raw material suppliers,” explains Anci Petersson, Sales & Marketing Director at Nolato Cerbo. “Our supplier, in turn, buys in the corresponding amount of bio-based raw material, mixes this with fossil raw materials and produces the granules that we use in our injection-molding machines.”

The exact same mix is also supplied to the raw material producer’s customers that did not order bio-based raw material.

Overall increase in bioplastic

“So although the product we manufacture is not manufactured from pure bio-based raw materials, we know that our order has increased the amount of bio-based plastic used overall in the plastics industry,” says Anci Petersson. “The method shares many similarities with developments within global electricity production; it’s the same electricity in the cables for everyone, but if you only choose electricity from renewable sources, the overall electricity mix is greener for everyone.”

- Sustainability

- Nolato

- Nolato Magasin

You might also be interested in

SUSTAINABLE DEVELOPMENT

Creating sustainable solutions

STORIES

Collaborating with universities and students

STORIES