Contact us

Sending Email...

FOCUS ON SUSTAINABILITY

Medical packaging: A case for plastic

Comparing tablet containers

The LCA screening was done on a tablet container generally used for drugs and supplements, read more about the specifics of the analysis here. A container used for drugs needs to fit a lot of requirements and regulations. For example, the container needs to be completely sealed and fulfill requirements regarding tightness against water vapor and UV-resistance. The materials that are most commonly used for this application today and therefore also the materials studied in the analysis are aluminum, glass, and plastic. As you can see in the graph the LCA screening clearly showed that a plastic container emits substantially lower amounts of carbon dioxide into the atmosphere over its lifetime compared to its alternative’s aluminum and glass.

This is true in spite of the fact that the glass and aluminum containers consist of 100% and 40% recycled material respectively, whilst the plastic container is made from 100% virgin fossil-based plastic. The nature of the pharmaceutical industry entails high requirements on the cleanliness and traceability of the packaging being used. Because of this, plastic containers used for drugs need to be fresh out of production as well as made from virgin material.

The plastic materials of the future

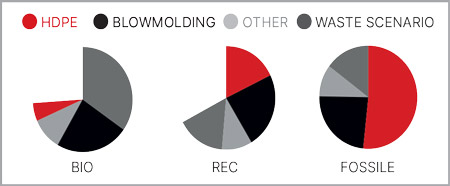

The LCA screening showed that containers made from bio-based plastics or recycled plastics have a considerably lower carbon footprint than regular virgin oil-based plastic containers, see the charts.

For recycled plastic, this is largely due to the fact that there is a lot less carbon dioxide emitted during the recycling process compared to the process of producing virgin plastic. For bio-based plastic, it is a combination of lower CO2 emissions during production and the fact that there is potentially no additional CO2 emitted into the atmosphere that had not been emitted by natural causes anyway, read more about bio-based plastics here. Recycled plastic has the lower CO2 impact of the two, but again, due to the regulations within the pharmaceutical industry, the use of recycled plastic is not permitted for pharmaceutical packaging at present. This is likely to change in the not so far future but until that day, bio-based plastics is the way to go.

Bio-based plastic is a drop-in solution evaluated in one of our standard product ranges. This means that we at Nolato have done all the necessary testing and evaluation already and the process of switching from fossil-based to bio-based plastic is just a matter of choosing to do so.

- Medical Solutions

- Sustainability

- Pharma packaging

- Medical Excellence

You might also be Interested in

MEDICAL EXCELLENCE

Creating world-class operations

STANDARD PRODUCT

Pharma packaging

SUSTAINABLE DEVELOPMENT