Contact us

Sending Email...

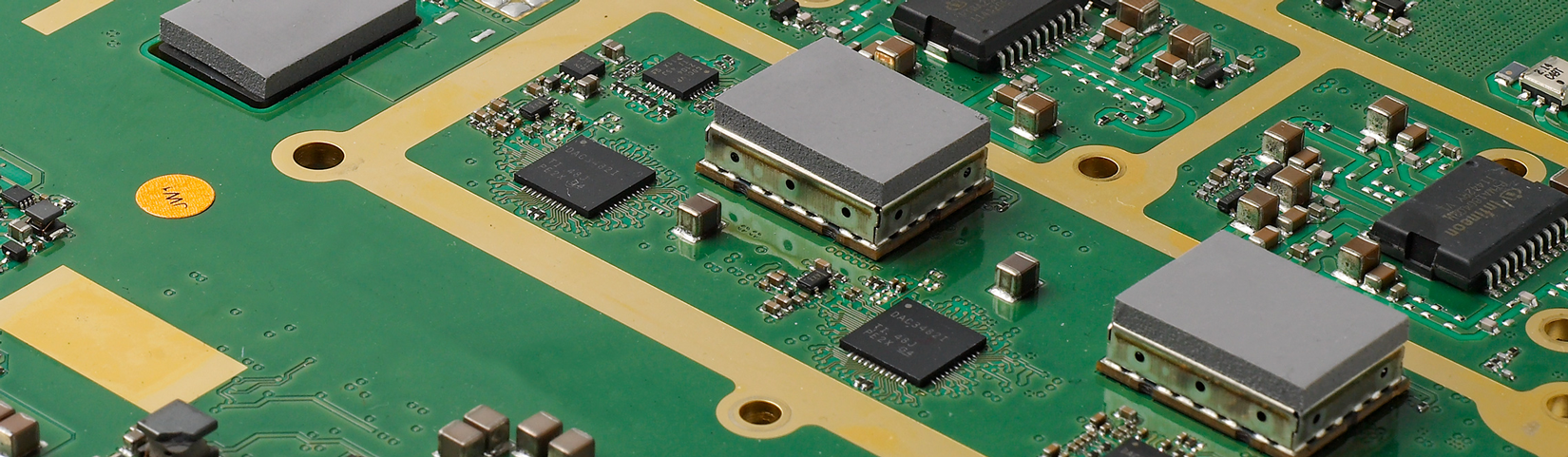

THERMAL MANAGEMENT

New silicone material provides efficient heat dissipation

Thermal management is a hot topic. How do you efficiently divert the heat generated by electronic components to ensure they’re not damaged?

Each new generation of electronic equipment gets smaller, while also offering greater capabilities and speed. But the combination of increasingly powerful and, consequently, hotter components packed tightly onto a small surface means the heat needs to be efficiently diverted away from active components. Otherwise the electronics could suffer damage.

This has resulted in thermal management becoming an increasingly important area for electronics engineers.

Heat sinks positioned above hot components have traditionally been used. But their efficiency is impaired by the fact that they do not have direct contact with the surface of the components.

“Filling this space with a thermal interface material, TIM, dramatically increases the cooling effect”, says Johan Falk, business developer at Nolato Silikonteknik.

Thermal interface material

Nolato Silikonteknik has developed an effective TIM based on the company’s extensive experience of solutions for electromagnetic compatibility (EMC). It is positioned directly against both the electronic component and the heatsink, filling the air pockets and irregularities that otherwise prevent heat dissipation.

The material is now used for more efficient cooling of electronics in the telecom, automotive, home electronics, IT and medical technology sectors.

“Our TIM, which we market under the Compatherm brand, consists of silicone that contains a thermal interface material with an electrically insulating filler,” says Johan Falk.

“This creates a soft but stable cushion that gives our product both good mechanical properties and an excellent ability to dissipate heat.”

CompaTherm is available in two forms; from a dispenser or as pads.

- Nolato Silikonteknik

- Thermal management

- Thermal Interface Materials

You might also be Interested in

SERVICE

Thermal interface materials and solutions

SHARE INFORMATION

The Nolato share

STORIES