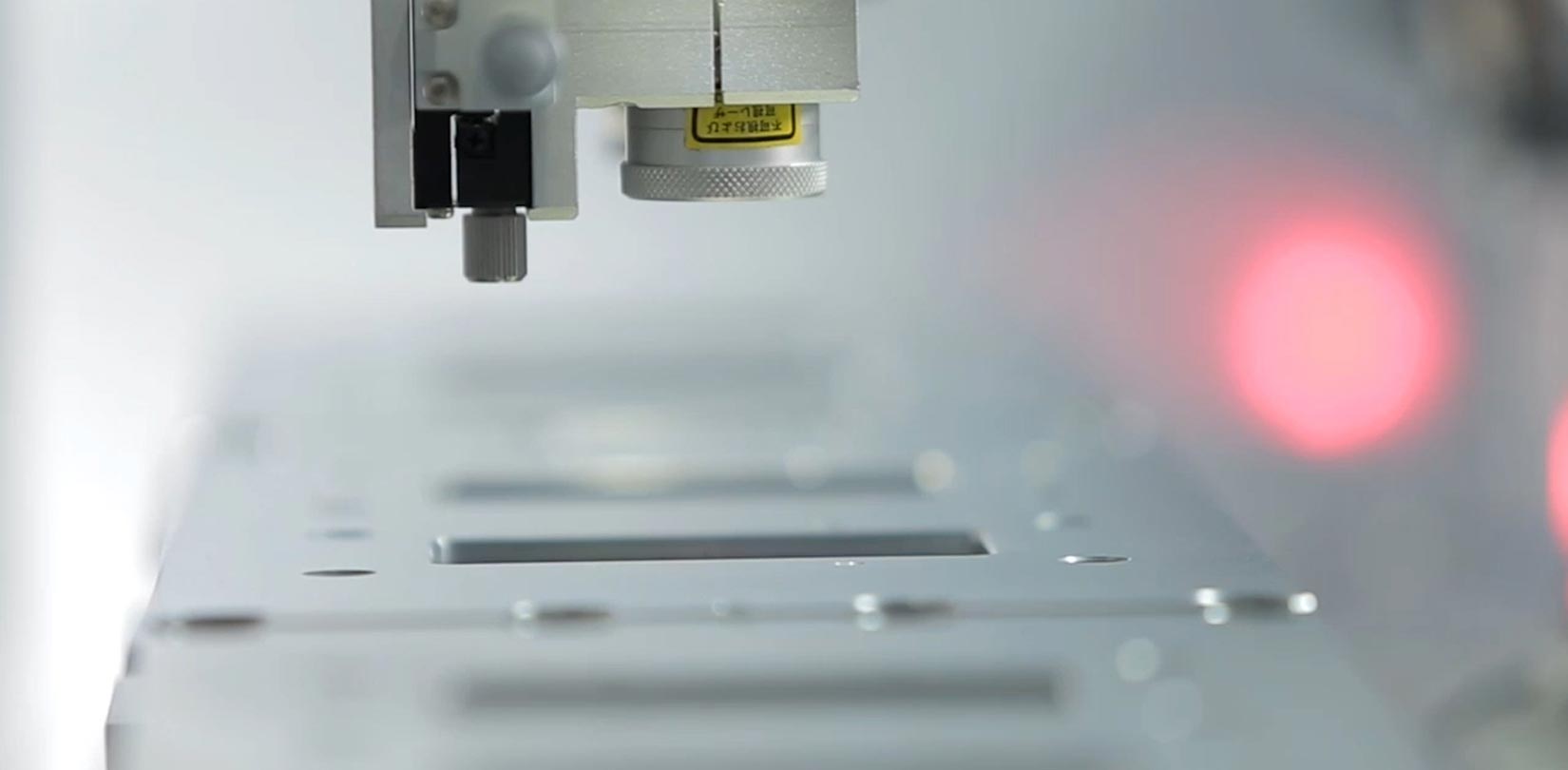

Laser-activated bonding is a technique developed by Nolato for assembling components of display screen panels and other applications.

SERVICE

Laser-activated bonding

Nolato's unique development of its laser-activated bonding system includes adhesive material development, manufacturing process design and laser activation equipment. It is particularly suited to consumer electronic products such as smartphones, tablet PCs, handheld game consoles, smart wearables and walkie-talkies.

A complete system

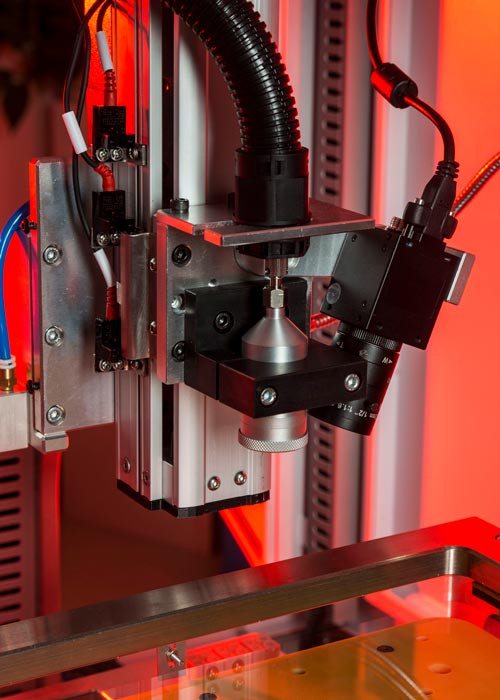

We have developed a complete system for our new bonding technique, including the laser equipment, adhesive pool and full process solutions.

Deactivated material

The material and its bonding forces can be deactivated through re-exposure to a laser beam, allowing easy reassembly or reworking of a component.

Display screen panels

We have developed a new bonding technique for the assembly of components such as display screen panels, especially panels with narrow bezels and waterproofing requirements.

Quick and efficient

The adhesive tape is activated immediately during assembly by being irradiated with a laser beam. No curing time is required, making the process quicker and more efficient than normal glue dispensing.

Reworking of materials

A major advantage of this technique is that, while it provides a strong bond, it is' easy to rework the materials if an error occurs in manufacturing.

Time saving

Efficient laser bonding saves time and resources.

TECHNOLOGY

Our waterproof technology

This new technique, which is based on a laser-activated adhesive, can be rapidly applied in manufacturing and provides a strong waterproof bond between materials.

PRODUCTION

Significant interest in our new technique

Our new technique has sparked significant interest among manufacturers, particularly of wearables like fitness trackers and smartwatches, as well as different types of handheld consumer products. Explore more in our video.

You might also be interested in

SERVICE

Dip molding

Nolato's extensive experience in dip molding with advanced process control ensures consistent output of high-quality products.

SERVICE

Injection molding of silicone

Nolato has over 40 years' experience in delivering cost-effective solutions for precision liquid silicone rubber (LSR) components and assemblies.

SERVICE

Micromolding

Nolato’s micromolding expertise enables the production of ultra-small, high-precision components using advanced materials and cleanroom manufacturing.