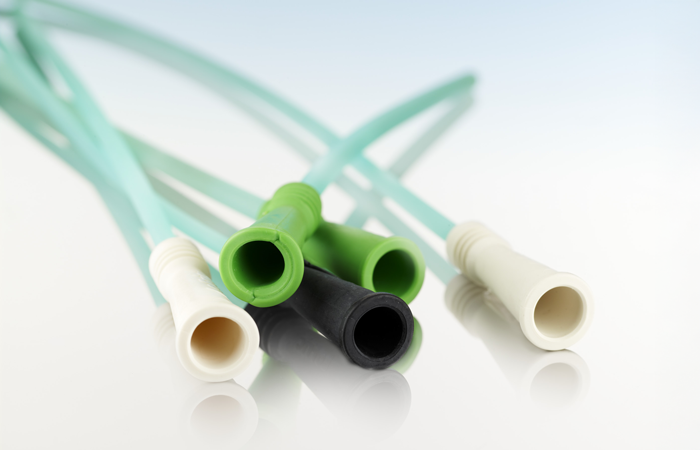

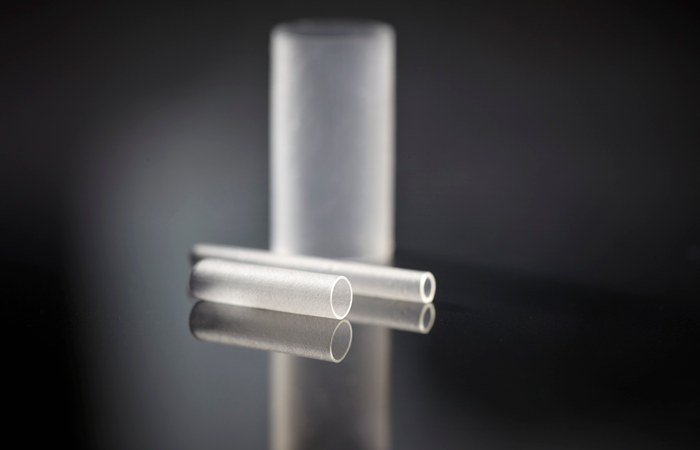

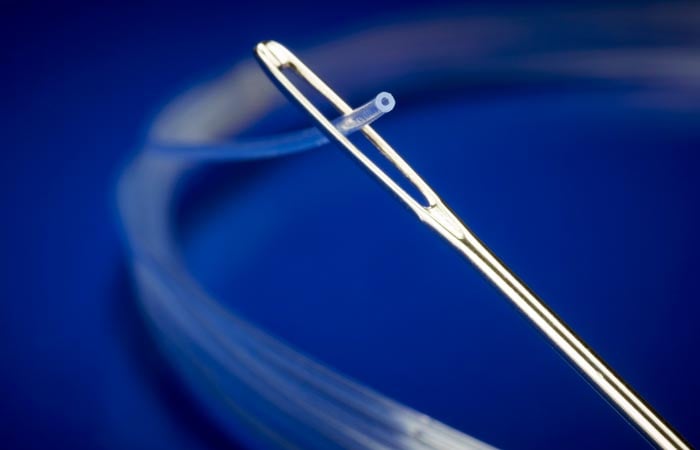

Nolato offers extrusion of medical-grade tubing with cleanroom production, as well as cut-to-length, tip-forming assembly of complete devices and other solutions.

Creating world-class operations

Medical Excellence is our way of creating world class operations inspired by the Nolato spirit, our strategies, quality standards and our lean processes and tools. Together, these elements create a framework for managing resources efficiently and increasing value for our customers.