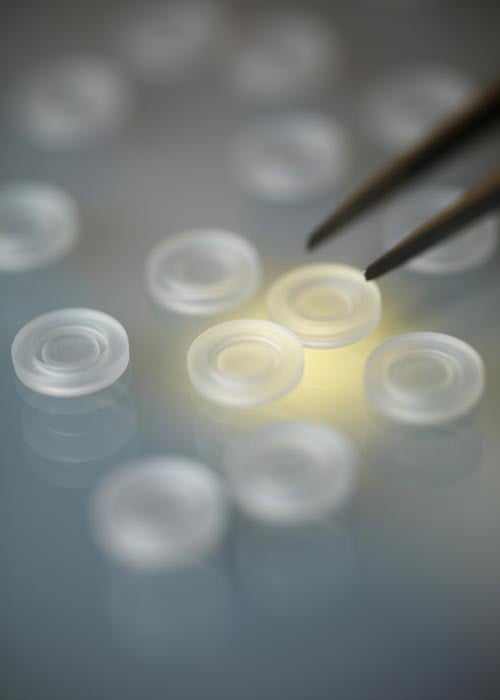

Nolato’s micromolding expertise enables the production of ultra-small, high-precision components using advanced materials and cleanroom manufacturing.

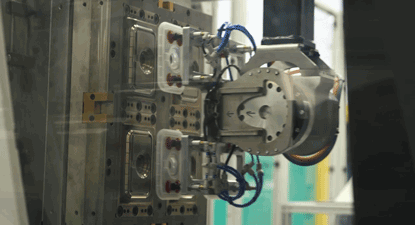

Injection molding of plastics

Discover Nolato's advanced injection molding services, offering precision solutions from 1K to 4K injection molding, including IML/IMD and single to high-cavitation molds for various industries.