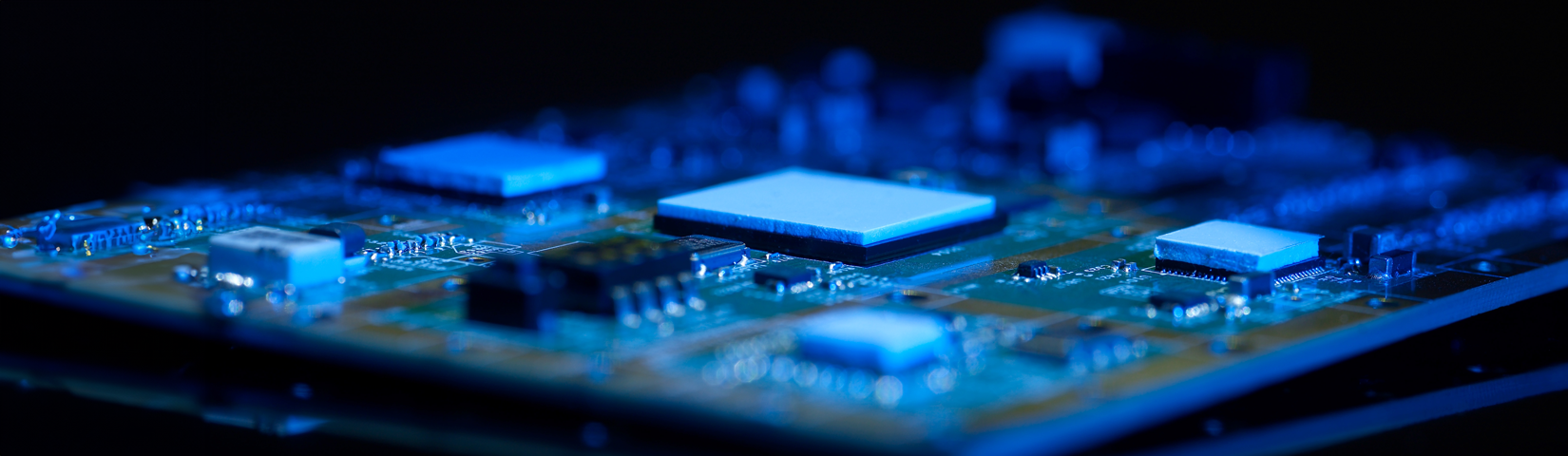

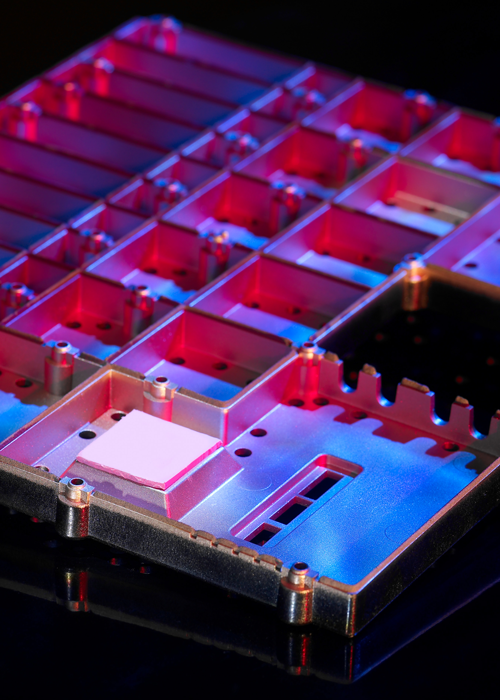

Unlock superior heat management with our thermally conductive silicone pads, engineered for efficient heat transfer in a wide range of electronic applications.

Contact us

Sending Email...

Contact person/s

Jonas Carlsson

Director Global Sales

+46 708 12 99 95

STANDARD PRODUCT

Compatherm Pad® : Thermal Heating Pads

These pads, designed to enhance cooling in devices provide an effective thermal interface that minimizes thermal resistance and maximizes heat dissipation, ensuring your electronics perform reliably at optimal temperatures.

Compatherm® Pad

Silicone Thermal Pads for Effective Heat Management

Our selection of silicone thermal pads uses high-quality materials designed to meet the most rigorous application requirements. These soft, thermally conductive silicone pads can be used where heat needs to be conducted between a component and a heat-dissipating surface, without any additional stress, or to bridge a gap for increased heat dispersion. Compatherm pads are available in a wide range of thicknesses, mechanical properties, liner solutions, and thermal performance.

Features of Compatherm® Thermal Pads

Superior heat conductivity

Achieve excellent thermal transfer with our silicone thermal pads, ensuring components stay cool under intense operations, enhancing device longevity and reliability.

Stress-free application

Soft and adaptable, these pads conform to surfaces at low pressure, ensuring a perfect fit for delicate electronics without risking damage during installation.

Versatile options

Choose the perfect fit from our selection, ranging from thermal conductive pads to specialized silicone thermal pads, catering to a wide variety of cooling needs.

Cost-effectiveness

Enjoy high-performance cooling solutions at competitive prices, allowing for efficient heat management without breaking the bank.

Tailored solutions

Leverage our customization options to meet specific thermal management challenges, offering personalized solutions that perfectly match your requirements.

Matrix and downloads

Compatherm® Pad Standard material matrix

| Test standard | Unit | 9420 | 9421 | 9423 | 9430 | 9431 | 9434 | 9440 | |

| Base matrix | Silicone | Silicone | Silicone | Silicone | Silicone |

Silicone | Silicone | ||

| Thermally conductive filler | Ceramic | Ceramic | Ceramic | Ceramic | Ceramic | Ceramic | Ceramic | ||

| Color | Visual | Lt Blue | Pink | Pink | Grey | Blue | Blue | Green | |

| Thickness Range | ASTM D374 | mm | 0.25-5.00 | 0.50-5.00 | 0.50-5.00 | 0.25-5.00 | 0.25-5.00 | 0.25-5.00 | 1.00-5.00 |

| Thermal Conductivity | ISO 22007-2 mod | W/(m-K) | 2 | 2.5 | 2.5 | 3 | 3 | 3 | 4 |

| Hardness | ASTM D2240 | Shore 00 | 40 | 40 | 60 | 60 | 40 | 40 | 40 |

| Density | ASTM D792 | g/cm^3 | 2.73 | 2.70 | 2.70 | 2.65 | 3.10 | 3.00 | 3.10 |

| Volume Resistivity | ASTM D257 | Ω·cm | 3.5x1012 | 8.5x1012 | 1.5x1014 | 2.1x1013 |

4.7x1014 |

3.4x1010 | 4.0x1012 |

| Dielectric Breakdown Voltage | ASTM D149 | VAC/mm | 5 000 | 5 000 | 5 000 | 500 | 8 000 | 8 000 | 8 000 |

| Dielectric constant @ 1MHZ | ASTM D150 | 6.33 | 7.47 | 7.09 | 22.8 | 7.43 | 5.66 | 7.90 | |

| Outgassing, TML | ASTM E596 Modified | % | 0.06 | 0.13 | 0.13 | 0.06 | 0.04 | 0.10 | 0.10 |

| Flammability | UL94 (file: E483565) | V-0 | V-0 | V-0 | V-0 |

| Test standard | Unit | 9450 | 9453 | 9460 | 9470 | 9471 | 9474 | 9480 | |

| Base matrix | Silicone | Silicone | Silicone | Silicone | Silicone | Silicone | Silicone | ||

| Thermally conductive filler | Ceramic | Ceramic | Ceramic | Ceramic | Ceramic | Ceramic | Ceramic | ||

| Color | Visual | Grey | Grey | Lt Blue | Lt Grey | Pink | Blue | Blue | |

| Thickness Range | ASTM D374 | mm | 0.50-5.00 | 1.00-5.00 | 0.70-5.0 | 1.00-5.00 | 1.00-5.00 | 1.00-5.00 | 0.50-5.00 |

| Thermal Conductivity | ISO 22007-2 mod | W/(m-K) | 5 | 5 | 6 | 7 | 7 | 7.5 | 8 |

| Hardness | ASTM D2240 | Shore 00 | 40 | 30 | 60 | 40 | 40 | 40 | 40 |

| Density | ASTM D792 | g/cm^3 | 3.10 | 3.16 | 3.24 | 2.55 | 3.10 | 3.30 | 3.10 |

| Volume Resistivity | ASTM D257 | Ω·cm | 3.2x1014 |

4.3x1012 | 5.32x1013 | 6.7x1012 | 3.1x1012 | 3.57x1011 |

1.0x1013 |

| Dielectric Breakdown Voltage | ASTM D149 | VAC/mm | 7 000 | 10 000 | 10 000 | 1 500 | 8 000 | 10 000 | 8 000 |

| Dielectric constant @ 1MHZ | ASTM D150 | 7.57 | 6.3 | 14.5 | 26.4 | 7.68 | 13.71 | 7.7 | |

| Outgassing, TML | ASTM E596 Modified | % | 0.04 | 0.2 | 0.13 | 0.23 | 0.3 | 0.1 | 0.3 |

| Flammability | UL94 (file: E483565) | V-0 | V-0 | V-0 |

Compatherm® Pad Soft material matrix

| Test standard | Unit | 9422 | 9433 | 9451 | 9472 | 9473 | 9475 | 94100 | 96160 | |

| Base matrix | Silicone | Silicone | Silicone | Silicone | Silicone |

Silicone | Silicone | Silicone | ||

| Thermally conductive filler | Ceramic | Ceramic | Ceramic | Ceramic | Ceramic | Ceramic | Ceramic | Ceramic | ||

| Color | Visual | Lt Blue/Lt Yellow | Grey | Grey | Lt Grey | Pink | Grey | Light Pink | Blue | |

| Thickness Range | ASTM D374 | mm | 0.50-5.00 | 0.50-5.00 | 0.50-5.00 | 1.00-5.00 | 1.00-5.00 | 1.00-5.00 | 0.50-5.00 | 0.75-5.00 |

| Thermal Conductivity | ISO 22007-2 mod | W/(m-K) | 2 | 3 | 5 | 7 | 7 | 7.5 | 10 | 16 |

| Hardness | ASTM D2240 | Shore 00 | 25 | 28 | 28 | 20 | 20 | 20 | 25 | 30 |

| Density | ASTM D792 | g/cm^3 | 2.73 | 2.65 | 3.07 | 2.55 | 3.10 | 3.10 | 3.20 | 3.13 |

| Volume Resistivity | ASTM D257 | Ω·cm | 8.4x1014 | 2.1x1013 | 3.2x1014 | 6.7x1012 |

3.1x1012 |

10.3x1011 |

TBD | 5.44x109 |

| Dielectric Breakdown Voltage | ASTM D149 | VAC/mm | 5 000 | 500 | 5 000 | 1 500 | 8 000 | 7 000 | 7 000 | >5 000 |

| Dielectric constant @ 1MHZ | ASTM D150 | 7.07 | 22.8 | 7.57 | 26.4 | 7.68 | 5.79 | TBD | 7.62 | |

| Outgassing, TML | ASTM E596 Modified | % | 0.1 | 0.06 | 0.04 | 0.23 | 0.3 | 0.31 | 0.3 | 0.26 |

| Flammability | UL94 (file: E483565) | V-0 | V-0 | V-0 | V-0 |

Compatherm® Pad Ultra-Soft material matrix

| Test standard | Unit | 9432 | 9441 | 9470s | 9612 | |

| Base matrix | Silicone | Silicone | Silicone | Silicone |

||

| Thermally conductive filler | Ceramic | Ceramic | Ceramic | Ceramic | ||

| Color | Visual | Brown | Green | Lt Grey | Lt Purple | |

| Thickness Range | ASTM D374 | mm | 1.00-5.00 | 1.00-5.00 | 1.00-5.00 | 1.00-5.00 |

| Thermal Conductivity | ISO 22007-2 mod | W/(m-K) | 3 | 4 | 7 | 12 |

| Hardness | ASTM D2240 | Shore 00 | 10 | 8 | 15 | 25 |

| Density | ASTM D792 | g/cm^3 | 2.92 | 3.10 | 2.55 | 2.86 |

| Volume Resistivity | ASTM D257 | Ω·cm | 2.1x1015 | 4.0x1012 | 6.7x1012 |

1.88x1012 |

| Dielectric Breakdown Voltage | ASTM D149 | VAC/mm | 7 000 | 8 000 | 1 500 | 10 000 |

| Dielectric constant @ 1MHZ | ASTM D150 | 5.48 | 7.90 | 26.4 | 11.58 | |

| Outgassing, TML | ASTM E596 Modified | % | 0.05 | 0.10 | 0.58 | 0.31 |

| Flammability | UL94 (file: E483565) | V-0 |

Compatherm® Pad Non-Insulating material matrix

| Test standard | Unit | 9610 | 9611 | 96290 | |

| Base matrix | Silicone | Silicone | Silicone | ||

| Thermally conductive filler | Carbon | Carbon | Carbon | ||

| Color | Visual | Dk Grey | Dk Grey | Black | |

| Thickness Range | ASTM D374 | mm | 1.00-5.00 | 1.00-5.00 | 1.00-5.00 |

| Thermal Conductivity | ISO 22007-2 mod | W/(m-K) | 14 | 16 | 29 |

| Hardness | ASTM D2240 | Shore 00 | 45 | 40 | 50 |

| Density | ASTM D792 | g/cm^3 | 2.70 | 2.76 | 2.35 |

| Volume Resistivity | ASTM D257 | Ω·cm | 500 | 500 | TBD |

| Dielectric Breakdown Voltage | ASTM D149 | VAC/mm | n/a | n/a | n/a |

| Dielectric constant @ 1MHZ | ASTM D150 | n/a | n/a | n/a | |

| Outgassing, TML | ASTM E596 Modified | % | 0.4 | 0.2 | 0.9 |

| Flammability | UL94 (file: E483565) |

Thermal EMI Absorber

| Test standard | Unit | 9442 | |

| Base matrix | Silicone | ||

| Thermally conductive filler | Ceramic | ||

| Color | Visual | Grey | |

| Thickness Range | ASTM D374 | mm | 1.00-5.00 |

| Thermal Conductivity | ISO 22007-2 mod | W/(m-K) | 4.50 |

| Hardness | ASTM D2240 | Shore 00 | 30 |

| Density | ASTM D792 | g/cm^3 | 3.40 |

| Volume Resistivity | ASTM D257 | Ω·cm | 1.04x1011 |

| Dielectric Breakdown Voltage | ASTM D149 | VAC/mm | 2 300 |

| Dielectric constant @ 1MHZ | ASTM D150 | 6.20 | |

| EMI Attenuation @10GHz | ASTM D 7449 | dB/cm | > 10 |

| EMI Attenuation @20GHz | ASTM D 5568 | dB/cm | > 30 |

| Outgassing, TML | ASTM E596 Modified | % | 0.3 |

| Flammability | UL94 (file: E483565) |

You might also be interested in

STANDARD PRODUCT

Compashield SMT Grounding Pad

Nolato delivers flexible SMT grounding pads and EMI shielding solutions. Engineered for demanding electronics applications, our products provide reliable electrical performance and durability under mechanical and environmental stress.

STANDARD PRODUCTS

Compashield®: Advanced EMI Shielding Gaskets for Optimal Protection

Compashield EMI shielding gaskets offer a comprehensive range of molded and extruded solutions tailored for EMI protection.

MATERIALS

EMC and Thermal Solutions

Nolato offers specialized EMI shielding gaskets, thermal interface materials, and IP sealing solutions. We provide standard EMC products and customized solutions, ensuring optimal EMI performance and efficient heat dissipation across various industries.