Improved design robustness by combining injection molding software with measuring software - Predictive tolerance analyses.

Contact us

Sending Email...

WHITE PAPER

Nolato's virtual factory

Welcome to our virtual factory

How to avoid

- Project delays

- Tool adjustments

- Molding imperfections

- Material changes

- Manufacturing defects affecting device functionality

- Delayed process qualifications

- Unpredictable outcomes

- Late and costly design changes

- Inaccurate measurements

- Expensive molds

Abstract:

As technology progresses, it becomes increasingly important to use virtual simulations to continue advancing and improving product development, manufacturing and industrialization workflows. Simulations offer a safe and cost-effective environment for optimization, testing and evaluation to identify the best design.

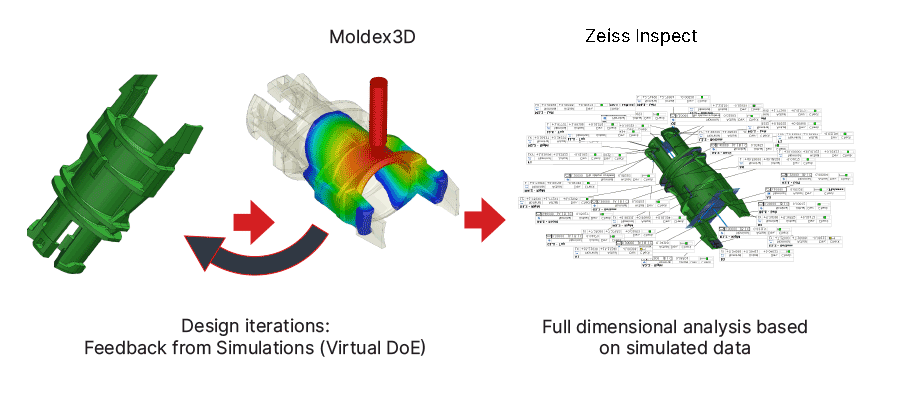

Virtual tools such as mold flow simulation software, mechanical simulation software and virtual measuring software provide project teams with invaluable data and information. Combining these tools enables you to revolutionize the development process and predict the final result on a whole new level. For example, providing full dimensional virtual measurement results for virtually manufactured components from mold flow simulations using the same measurement principles and machine parameters that will be used for physical components at a later stage.

Design and tolerances:

The successful development of new products within the medical device industry requires close collaboration between designers/customers and manufacturers. Confidence and control of product functionality is key to achieving the perfect balance between focusing on critical dimensions and allowing wider tolerances for less important features. Our recommendation is therefore to use tolerance analysis software to shorten lead times and build confidence in the design.

Tolerance standards for plastic molded parts, taking account of material selection and production conditions, should also be used as a guideline and reference for dimensional reviews.

Data-driven mold design:

Are you seeking excellence in your injection mold design and want to reduce the number of unnecessary tool iterations to cut time to market?

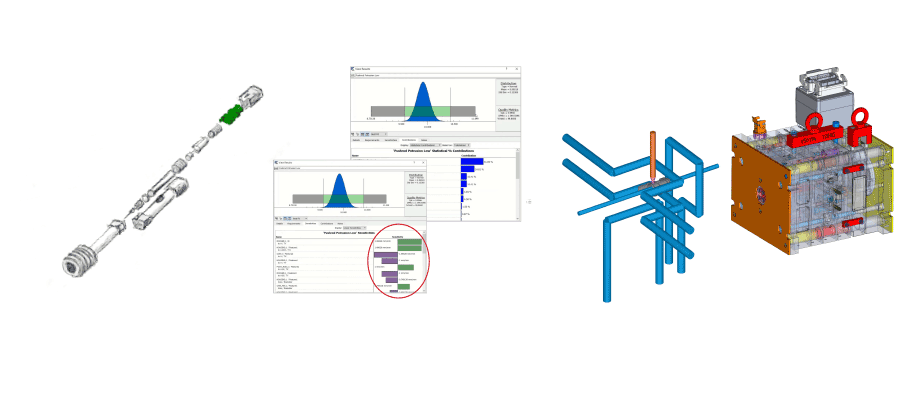

The solution is to bring us on board at the early development phase. Using a virtual toolbox consisting of advanced mold flow simulations, FEA simulations, tolerance analysis software and combining them with the power of dimensional evaluation in measuring software, it’s possible to predict outcomes and effectively evaluate different design options with high confidence.

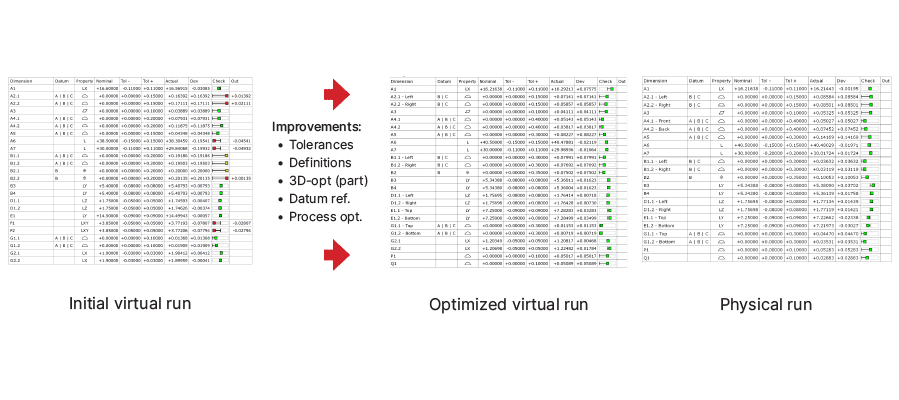

In the software, we fine-tune gate positions, evaluate cooling layouts and optimize the design from a molding and product perspective. Molding imperfections such as sink marks, air enclosures and weak areas are identified at an early stage and can then be resolved or reduced. By using a measurement program, developed in parallel with the design work, complete virtual measurement reports can be provided for all virtual test runs and DOEs. This makes it more efficient to analyze and select the best design track.

Steel strategies:

Adjusting injection molding molds after the First Out of Tools (FOT) can pose several risks, including incorrect adjustments, tool damage and, cost overruns and more. We believe in using steel strategies to compensate for warpage and displacement upfront, identified during virtual runs with virtual measurements. This applies not only to surfaces that are steel safe (steel added with intention to remove), but also remove steel upfront (more aggressive approach).

This saves time and will results in higher accuracy than adjusting the mold afterwards.

Robust measurement strategies:

We support customers with metrology expertise in the early development phase. This involves providing advice and working together to come up with robust measurement methods and to define the individual dimensions to secure product functionality and a reliable control method.

The measuring software normally used for 3D scanning is developed based on virtually manufactured models (from mold flow simulation). Measuring software can evaluate all kinds of dimensions of virtual components. The benefit of this is that we can check all dimensions from the simulation, and also review the checks from a functional point of view and verify the strategies upfront.

Shorter lead times: Simulations allow you to identify any molding issues or design issues early on in the process, reducing lead times for product development and the risk of delays later on due to unidentified issues.

Measurement agreements:

Even if Model Based Definitions are being used, the most common way of defining dimensions and tolerances is still using 2D drawings. The main problem with 2D drawings is ambiguous definitions of dimensions, which could result in additional work and misinterpretations during measurements and evaluations.

To mitigate the risk of this, measurement agreements should be established between manufacturer and designer/customer in which every dimension is set out in detail using text and images. The same applies to alignments and datum systems, i.e. anything that could have an impact on the result.

Control and alignment are important.

Mold qualification:

Mold qualification greatly benefits from using the combined strength of virtual tools: virtual manufacturing, virtual testing and virtual evaluation. Simulations and a robust design significantly enhance mold qualifications by optimizing the mold design, detecting potential issues early on, saving time and costs, ensuring precise tolerance analysis and facilitating regulatory compliance.

The virtual factory will have already prepared initial settings for run-in, evaluated the process window, and identified and resolved weaknesses, ensuring higher success rates during qualification.

Since measurement programs will have already been developed during the evaluation of virtual samples, time saving and risk mitigations will have also been established in this respect and will be ready to evaluate physical samples.

Conclusion: if you want to optimize your product development process and ensure high product quality, bring us on board, preferably before the design is frozen and molds have been ordered.

Let’s join forces for a successful outcome: Our team of experts is ready to support you in developing state-of-the-art products, optimized for high-volume production.

Director Technical Design Center (TDC) Europe

Patrik Ingvarsson

- Nolato

- Technical Design Center

- Sustainability

You might also be interested in

SUSTAINABLE DEVELOPMENT

Creating sustainable solutions

ABOUT US

The Nolato Spirit

OUR APPROACH TO PRODUCTION