Contact us

Sending Email...

GREEN THINKING

How TDC Plays a Crucial Role in Making Products More Sustainable

As a solid science-based company, Nolato is constantly looking for solutions to innovate product design and manufacturing processes to obtain the best results for its customers. To achieve excellence in developing and manufacturing sustainable and robust plastic components across Nolato’s companies globally, the company’s Technical Design Center (TDC) plays a crucial role. TDC is a global support function and a central hub within Nolato, acting as an interface between production sites and customers, sharing knowledge, best practices, troubleshooting and providing support to customers regarding product design, materials and efficient production.

The resources and support provided by the TDC are applied to both of Nolato’s business areas: Medical Solutions and Engineered Solutions. The TDC team comprises approximately 35 specialists organized into four units that operate across the regions of Nolato, namely the USA, Europe and Asia.

From Cradle to Grave/Gate mindset

The TDC operates with a holistic approach, evaluating every aspect of product development and production from cradle to grave/gate. This includes product design—focusing on functionality, material selection, manufacturing techniques, and product lifespan, while also considering end-use dismantling, recycling opportunities, and more.

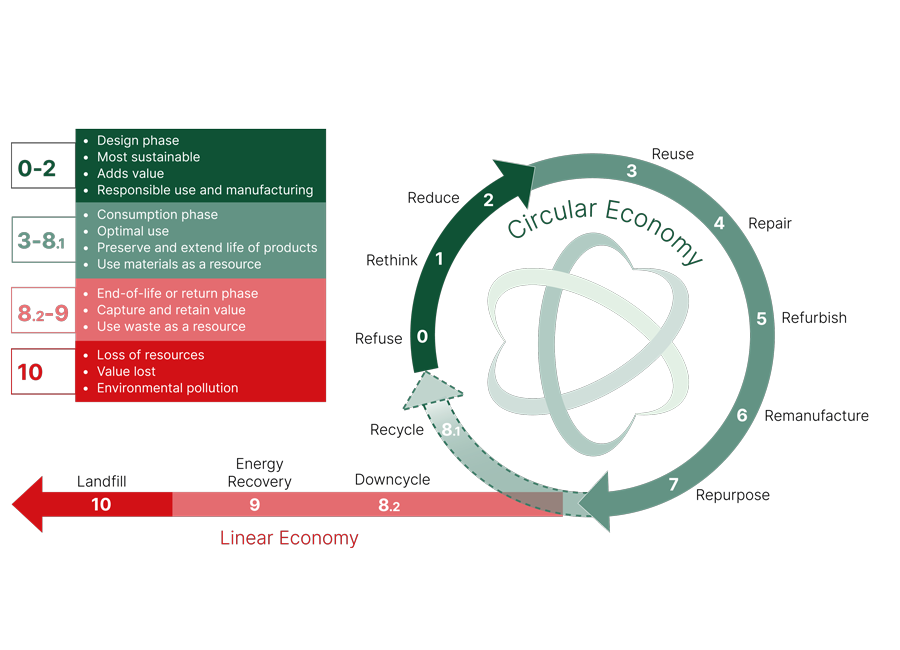

Figure 1 – Nolato’s “R” strategy for transitioning towards a circular economy model based on Eco-Design principles

To optimally leverage the expertise of TDC, it is ideal to involve the team early in the product development phase. This enables TDC to review and evaluate a product’s foundation and prospects while providing valuable support and input on how to adapt and design for optimal functionality, and cost-effective manufacturing, as well as ensuring a strong element of sustainability from the outset. This early involvement of TDC is a strategic component of the Nolato value proposition, as it allows customers to optimize their products during the initial stages, delivering high value, maximizing yield for customer’s business and reducing time-to-market.

Sustainability as the center of innovation

Over the years, the demand for sustainable products across all industries has significantly increased. This trend is further reinforced by a legislative landscape that imposes diverse requirements for ESG (Environmental, Social, and Governance) objectives and reporting obligations on businesses. Key frameworks, such as the EU Eco-Design Directive, emphasize environmental sustainability by improving energy efficiency, resource use, and reducing environmental impact throughout a product's lifecycle.

As one of its core assignments, TDC supports product innovation for sustainable solutions, for which Nolato has developed a customized Eco-Design model.

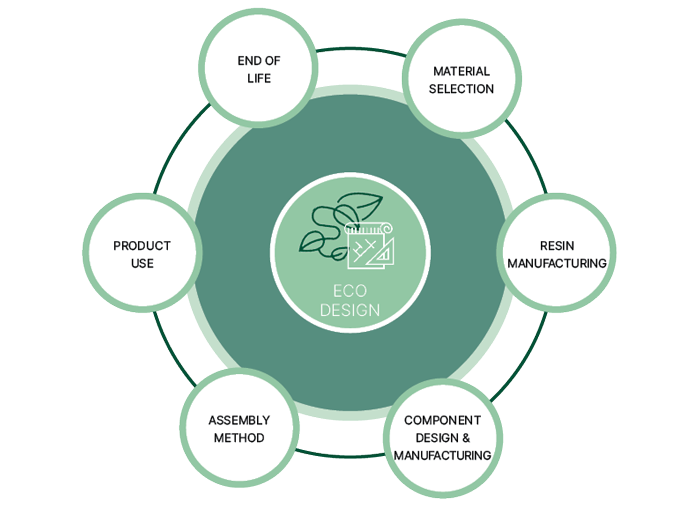

Figure 2 – Nolato’s Eco-Design principles

This framework provides TDC with a sustainability-driven approach to effectively and comprehensively design, review and optimize customers’ products, improving their sustainable footprint. The model emphasizes the early integration of sustainability in the design process to ensure it is embedded at every key stage of a product's lifecycle.

- Material selection, emphasizes choosing eco-friendly, recyclable, mass-balanced or biodegradable materials to minimize environmental impact.

- Resin manufacturing, an integral part of production, evaluating raw materials for material production and prioritizing low-emission processes and the use of renewable resources to reduce carbon footprints.

- In component design and manufacturing, energy-efficient methods and durable designs are key to extending product lifespan and minimizing waste.

- Lastly, assembly methods, product use, and end-of-life strategies focus on optimizing energy consumption during use and ensuring responsible disposal or recycling, making the model essential for creating sustainable products throughout their lifecycle.

These different areas complement each other, enabling TDC to assess every aspect of a product's environmental impact.

As previously emphasized, Nolato aims to be involved early in the product development phase, and this very much applies with regard to sustainability as well. By supporting customers during this phase, the TDC team can make a significant impact on improving sustainability while ensuring the functionality and robustness of the product, as opposed to working with products already on the market.

Furthermore, sustainability presents a favorable opportunity from a cost standpoint. In fact, eco-design and cost-efficient production are closely aligned. Efficient design choices, such as selecting durable/effective/low-footprint materials, optimizing part design, or minimizing waste, can deliver significant environmental and financial benefits. Done right, there is often a correlation between production efficiency and sustainability, as both aim to reduce resource consumption and waste. Strategies like using less material, designing for energy-efficient production, and adopting mono-material design principles are not only cost-efficient from a manufacturing perspective but also align with sustainability aims of reducing the overall environmental impact of a product.

TDC has long been a trusted provider of sustainability expertise, offering guidance and innovative ideas to help Nolato’s customers place sustainability at the core of their product development.

Collaborating closely with customers and suppliers – MELITEK A/S case

For decades, TDC has partnered up with customers with the aim of fostering mutual learning and advancements in product design and technologies. One of TDC’s focus areas when working with customers is understanding and using resources in an optimal manner for which advanced analytical tools are applied to study the interlinks between the functions of a product and the design of its respective components.

As an example of a recent customer-supplier collaboration, Nolato and MELITEK A/S worked together to explore material substitutions for improved sustainability without compromising engineering performance. MELITEK A/S is a privately owned Danish company specializing in elastomer and polymer compounds based on 30 years of experience servicing the healthcare market. The project focused on replacing a conventional polycarbonate/acrylonitrile butadiene styrene (PC/ABS) blend with a customized polypropylene (PP) compound for a medical device component, specifically modified to replicate the mechanical properties of PC/ABS while ensuring compatibility with existing production equipment.

Nolato’s TDC conducted an initial technical study to assess the feasibility of this material transition, with a primary focus on determining whether the modified PP compound could meet dimensional requirements without requiring mold modifications. The study evaluated critical factors such as shrinkage behavior, warpage, and dimensional stability. While the results indicated some challenges in achieving all dimensional requirements, the modified PP compound demonstrated good potential for successful integration with further optimization of material formulation or processing parameters. Additionally, TDC examined the material’s processability in the current injection molding setup, assessing flow behavior and necessary process adjustments to maintain part consistency.

The material substitution could lead to significant reductions in energy consumption, raw material usage, and overall carbon footprint. The reduction in raw material usage is primarily due to PP’s lower density compared to PC/ABS, enabling a lower material mass per part while maintaining structural integrity.

Figure 3 – TDC engineers analyzing process parameters in Nolato’s Molding Laboratory in Hörby, SE

While this specific PP is fossil-based, it has a lower CO₂ footprint than PC/ABS due to its more efficient production process and lower material density. Additionally, this project demonstrates the potential for further sustainability improvements, as future advancements in bio-based or mass-balanced PP formulations could further reduce environmental impact. The study highlights the feasibility of transitioning to a lower-impact material, with further refinements needed to fully meet dimensional requirements, making it a promising step toward more sustainable injection-molded components.

The Technical Design Center (TDC) plays a crucial role in making products more sustainable by integrating eco-design principles early in development, optimizing material selection, enhancing manufacturing efficiency, and collaborating with customers to reduce environmental impact while maintaining performance and cost-effectiveness.

- Virtual prototyping

- Technical Design Center

- Nolato Magasin

Technical design center (TDC)

Locations: Baldwin, WI, USA / Hörby Sweden / Beijing, China. Supports global customers with expert guidance in product design, materials, and sustainable manufacturing. With specialists in Europe, Asia, and the USA, TDC helps optimize performance, cost-efficiency, and environmental impact - right from the start.

You might also be interested in

SERVICES

Virtual prototyping

STORIES

Expanding Minds Across Nolato

STORIES