Contact us

Sending Email...

STORIES

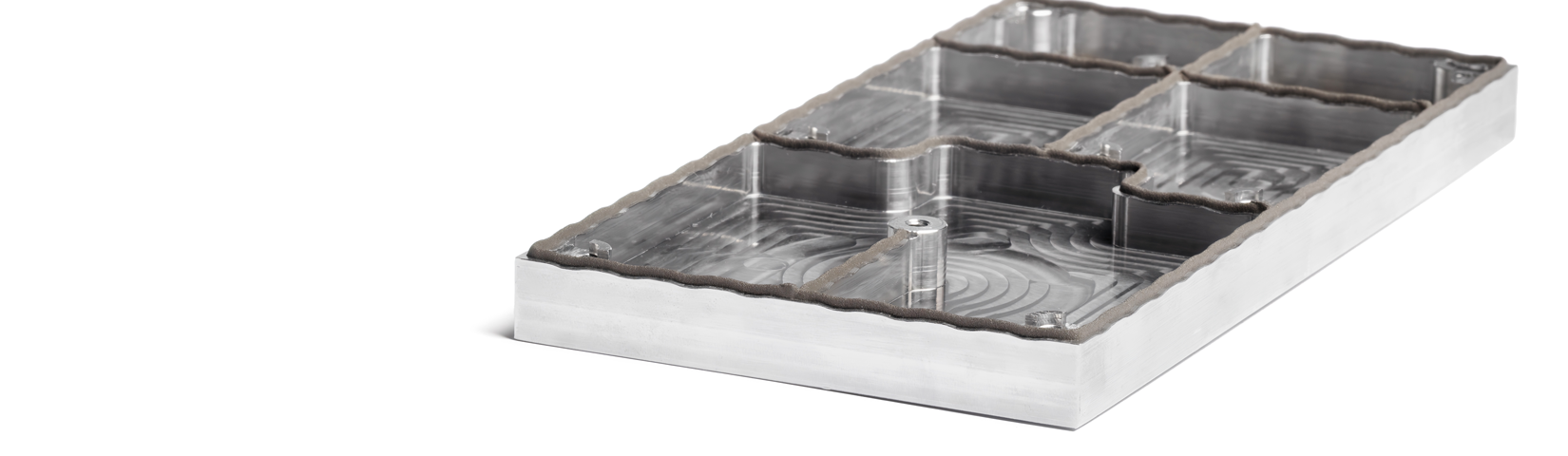

Trishield RTV: Revolutionizing EMI Shielding

Nolato is Setting the Industry Standard for EMI Shielding Solutions With Its New Trishield RTV Technology

For over 20 years, Nolato has developed and provided Trishield technology for electromagnetic interference (EMI) shielding, serving high-tech industries and companies in relation to providing different gasket sealing solutions. This is critical in preventing unwanted electromagnetic signal disruptions, for instance in electronic devices and modern cars. Thus, Nolato Trishield solutions have served for decades as a key technical tool in meeting EMI requirements, ensuring the performance and reliability of devices in various industries.

Over the years, the Trishield technology has been developed internally across Nolato companies, namely by Nolato Silikonteknik in cooperation with Nolato’s US-based sister company Jabar. Stemming from this cooperation, the new Trishield RTV technology has emerged and taken center stage, representing a milestone for innovation and Nolato's long-standing focused R&D efforts.

The new functions and advantages of Trishield RTV

The new Trishield RTV (room temperature vulcanization), introduces advanced features, delivering an EMI shielding solution that combines high shielding effectiveness with strong mechanical performance. Whereas previous Trishield versions relied on heat curing systems that were unsuitable for gaskets in heat-sensitive materials, the new Trishield RTV features allow for curing at room temperature, expanding its applicability to a wider range of designs and materials. This advancement opens new application areas, making Trishield RTV particularly well-suited for products that incorporate heat-sensitive materials, such as plastic, magnesium, or surface-treated aluminum.

Due to its narrow and high gasket profile, the new Trishield RTV significantly reduces material usage, contributing to a more efficient design. The reduced material usage is valuable both when the gasket is used as a traditional gasket and cured in place as well as an adhesive, to glue things together. For example, cover and printed circuit board. This reduction in material not only lowers production costs but also decreases the required compression force and minimizes the number of screws needed for assembly. Overall, this translates to tangible cost savings, making Trishield RTV an economical and efficient choice for EMI shielding.

Nolato will continue to develop its Trishield RTV solution by further refining the gasket properties while working with different materials to stay ahead of the curve. This approach ensures that Nolato can meet the growing demand across industries for innovative EMI shielding solutions. This is important as an increasing number of everyday products incorporate integrated electronics, which are becoming smaller, more powerful, and more interconnected — particularly in consumer electronics, automotive and electric vehicles, and medical devices.

- EMC products

- Nolato Silikonteknik

- Materials

- Nolato Magasin

- EMI shielding

- Nolato Jabar

You might also be interested in

STANDARD PRODUCTS

Trishield® EMI Shielding FIP Gaskets

PRODUCT GUIDES

Our thermal and gasket guides

SERVICE