Located in India, Nolato Bangalore, a manufacturing site established in May 2024, provides electromagnetic interference (EMI) shielding and thermal interface solutions.

Contact us

Sending Email...

GROUP COMPANY

Nolato Bangalore

We offer unique premium solutions in conductive silicone and thermal interface materials (TIM), in combination with local production on a global scale. All materials are serving global customers in the Telecom, Automotive, Medical, Aerospace and Electronics industries sets the highest standards for all our products.

examples of products

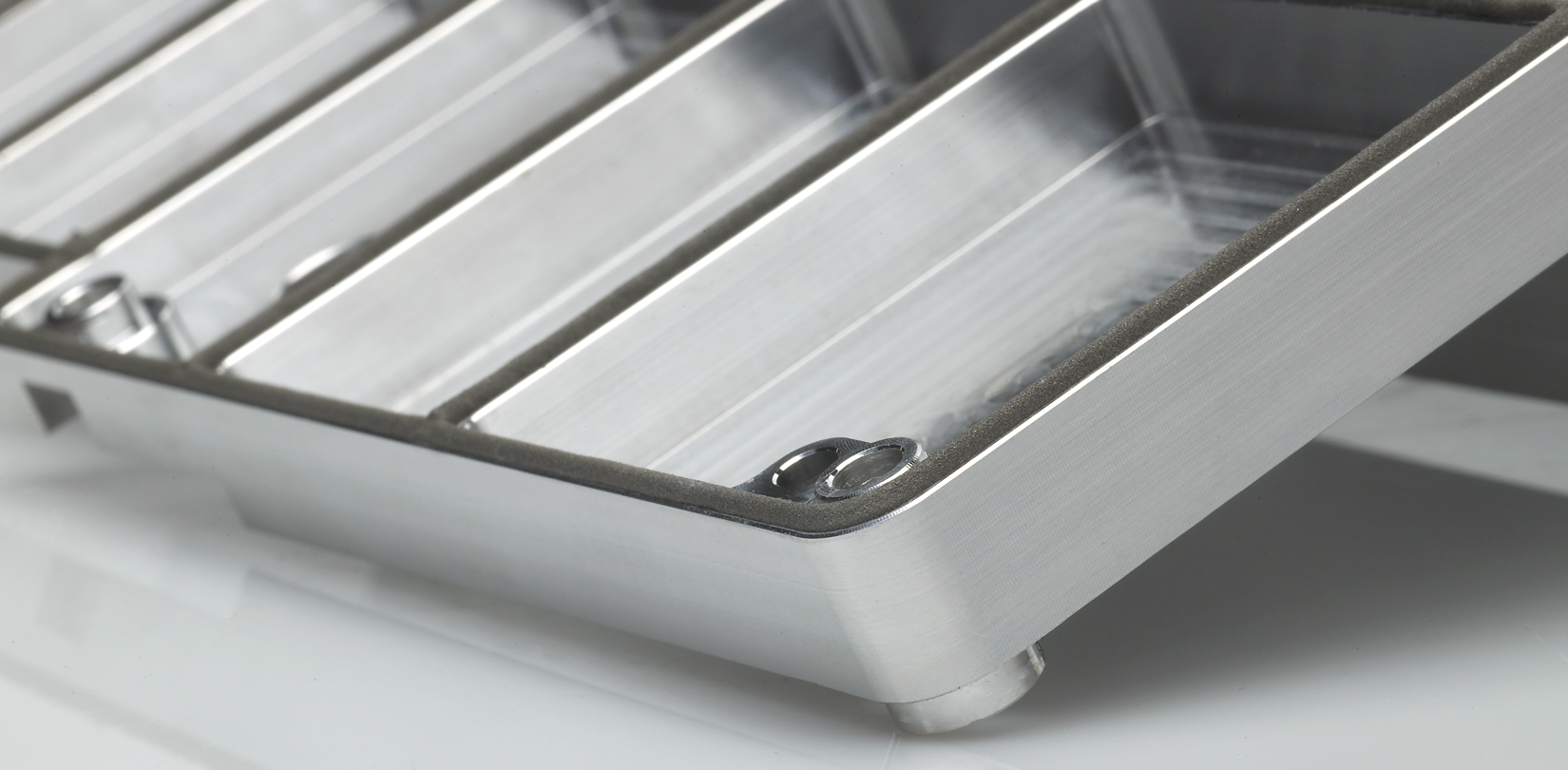

- Compashield extruded gasket

- Compatherm Thermal Pad

- Compatherm Filler dispensing

- Trishield FIP gasket

- Compatherm Thermal Paste

Our site

Nolato Bangalore is part of the Engineered Solutions business area of the Nolato Group.

Contact

If you would like to find out more about Nolato Bangalore's services and products please contact our team member or use the form at the bottom of this page.

Sandeep KJ

India – Sales Manager

Ankit Sharma

India - General Manager

Standard products we offer

STANDARD PRODUCT

EMC products

Nolato utilizes electrically conductive silicone, coupled with extensive expertise and experience, in our electromagnetic interference (EMI) shielding solutions for electromagnetic compatibility (EMC). Our high-performance MIL SPEC EMI shielding products ensure integrity and quality in aerospace, automotive and telecommunication applications.

STANDARD PRODUCT

Thermal Interface Materials

Our thermal interface material (TIM) portfolio and our leading expertise in this field provide you with support and solutions for optimal efficiency and cost savings in electronics cooling. We have the know-how and resources to guide you throughout the thermal interface material process.

Would you like us to contact you instead?

Please fill in the form and select your preferred method of contact and we will get back to you as soon as possible.

You might also be interested in

INDUSTRY

Automotive

Nolato are a leading provider of electromagnetic interference (EMI) shielding and thermal interface solutions.

INDUSTRY

Telecom

Nolato provides EMI shielding, thermal management, and IP sealing solutions for the telecom industry, ensuring reliable performance in 5G infrastructure, base stations, and routers. Our expertise in customized solutions and high-volume manufacturing makes us a trusted partner for telecom equipment manufacturers.

INDUSTRY

Aerospace

Nolato's electromagnetic interference (EMI) shielding, thermal interface, and silicone sealing and damping products are widely used in the aerospace industry.

Stories

STORIES

Be-Må Molds joins the Nolato group

Nolato has acquired tooling firm Be-Må, which has been renamed Be-Må Molds in the Nolato Group. The company, based in Värnamo, Sweden, makes precision tooling for the injection molding of medical and other products.

STORIES

Nolato’s new Head of Sustainability

Sustainable development is one of the most important aspects of running a business today. It’s about continually reducing the company’s negative impact on people and the environment, or simply taking on our share of responsibility.

STORIES

Reducing production related emissions

We want you to know that we at Nolato are pushing ourselves, and want do do more than what is demanded of us. Do you want to read more about what we do to reduce the harmful emissions? Read more about how we work with ISO 50001 at Nolato Jaycare, and how we clean gas emissions at Nolato Beijing here.