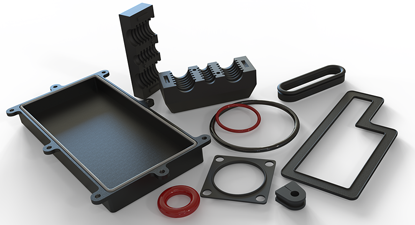

Trishield® is Nolato’s form-in-place (FIP) EMI gasket solution, developed for compact electronic enclosures and space-constrained housings in high-volume production environments.

This white paper presents a technical evaluation of geometry-driven form-in-place (FIP) EMI gaskets, using Trishield® as a representative implementation. Conventional conductive silicone gaskets are typically designed by increasing filler content, and thereby material stiffness, to achieve shielding effectiveness, which often leads to high assembly forces, increased material usage, and limited tolerance absorption.

The study explores an alternative, geometry-driven approach, where the gasket cross-section is engineered to achieve a high height-to-width ratio triangular profile without increasing footprint width. This geometry enables effective EMI shielding while improving compressibility, reducing required clamping forces, and minimizing material usage.

The paper discusses how gasket geometry influences shielding effectiveness (SE), mechanical behavior under compression, conformity to irregular gaps, and implications for enclosure design and fastening strategies. Manufacturing considerations, including suitability for high-volume automated dispensing and process robustness, are also addressed.

Rather than focusing solely on component-level performance, the white paper provides a system-level perspective on EMI sealing that aligns EMC requirements with mechanical design and industrialization constraints in modern electronics. The evaluation includes shielding effectiveness measurements across a broad frequency range relevant to modern high-speed electronics and is intended for engineers and technical teams evaluating EMI shielding solutions for compact, high-volume electronic platforms.