Selecting the right SMT grounding pad has a direct impact on PCB performance, EMI/EMC behavior, and long-term reliability — especially in applications exposed to mechanical load, compression, temperature fluctuations, or humidity. This white paper compares two common grounding pad constructions and highlights how different material and design choices influence electrical contact stability over time.

The summary on this page highlights only high-level insights.

All detailed data, graphs, tables, and failure analysis are available exclusively in the downloadable PDF.

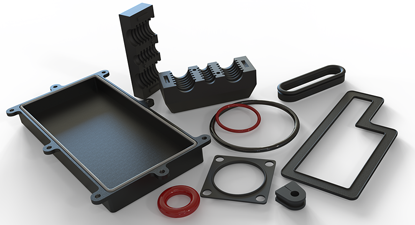

This white paper presents a comparative evaluation of two SMT grounding pad designs widely used in PCB applications: a conductive silicone-based SMT pad and a foil-wrapped silicone pad. Both are intended as solderable grounding components that replace traditional metal spring contacts, but their construction differs significantly, resulting in different performance behaviours over time. The study focuses on the key factors that influence grounding pad reliability, including compression response, mechanical durability, electrical resistance, and impedance stability across relevant frequency ranges.

To assess long-term performance, the grounding pads were tested under mechanical compression levels up to 80% and evaluated through accelerated aging conditions such as 1,000 thermal cycles between –40 °C and +125 °C and 1,000 hours at 85 °C / 85% RH. These conditions reveal how material choices, conductive mechanisms, and structural design influence the pads’ ability to maintain consistent electrical contact over time. Differences in durability, deformation resistance and contact integrity become especially visible under combined environmental and mechanical stress.

The findings highlight how grounding pads that appear similar in initial specifications can diverge significantly in performance when exposed to real-world conditions. Understanding how conduction paths, material interfaces, and design geometries behave under stress is essential for selecting reliable grounding components for advanced electronics.

This white paper provides engineers, PCB designers, EMC/EMI specialists and reliability teams with key insights to support informed decision-making when evaluating grounding pad technologies for long-term robust performance.