At Nolato Treff AG, cutting-edge automation technologies—driven by AI, robotics, and a commitment to sustainability—are revolutionizing quality assurance and production agility.

Contact us

Sending Email...

STORY

Innovation driving superior quality

In today’s manufacturing landscape, efficiency, quality, and flexibility are crucial. Oliver Büchel, responsible for automation at Nolato Treff AG, shares insights into the latest advancements that are revolutionizing injection molding production through state-of-the-art technologies.

Artificial Intelligence Ensures Top-Level Quality Assurance

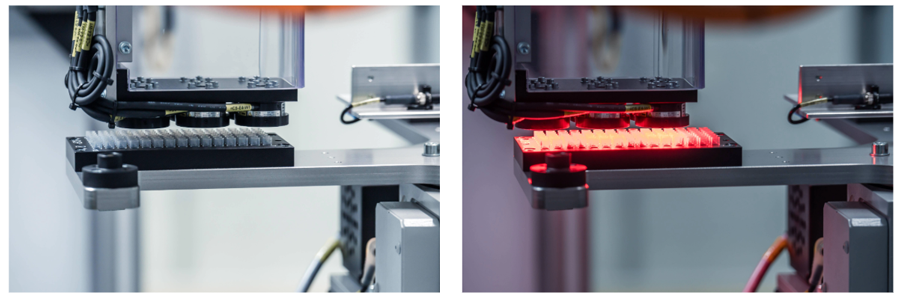

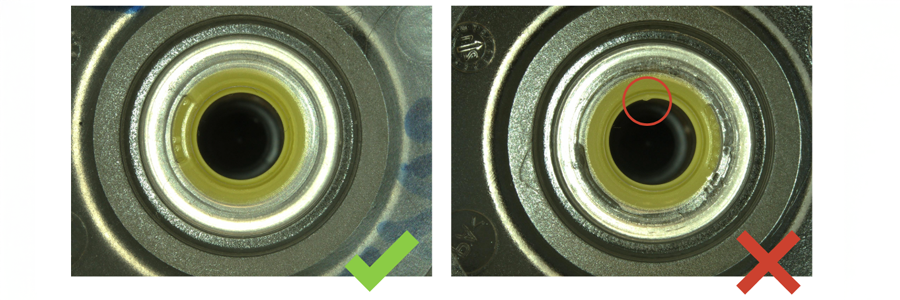

A key innovation at Nolato Treff AG is the use of artificial intelligence (AI) in quality control. This is particularly vital for the production of complex plastic components with stringent quality requirements, such as those used in the medical and food industries. AI-supported camera systems detect even the smallest defects—imperceptible to the naked eye or conventional cameras.

For instance, surface quality of micro-components is verified or radial shaft seals from suppliers are checked for irregularities. These AI systems are trained to identify anomalies in shape, size, and material consistency with precision, while distinguishing harmless production variations, significantly reducing scrap rates.

"These technologies not only eliminate defects but also allow us to adjust production speeds while consistently meeting our high-quality standards," emphasizes Oliver Büchel.

Continuous Monitoring of Inspection and Measuring Systems

Measurement systems are only effective if they function correctly. That’s why all testing and measuring systems integrated into our automation lines are regularly verified in a fully automated process. Production halts automatically if the verification fails.

"This clearly reflects Nolato’s strong commitment to quality and ensures high production reliability. It guarantees that no defective parts reach the customer and that any potential measuring system faults are detected early," Büchel explains further.

Advanced Robotics for Agile Production

In addition to AI, Nolato Treff AG relies on cutting-edge robotics. A flexible feeding system enables robots to pick components with precision using camera data, adapting swiftly to varying part sizes. Thanks to an automated quick-change gripper system and rapid emptying functions, product changeovers take only minutes.

In another application, a robot autonomously loads transport carts in a cleanroom environment—essential for hygiene and efficiency. This robotic arm operates in a semi-collaborative mode: it slows down automatically when changing carts and resumes normal operation when a new cart is ready. This is a seamless blend of flexibility and efficiency.

Greater Sustainability Through Smart Automation

Nolato Treff AG’s drive for innovation is rooted not only in technological excellence but also in a strong sense of environmental and social responsibility. Sustainable production methods, early detection of process deviations, and adherence to stringent quality and safety standards all play a role. The better the processes are planned and managed, the lower the levels of waste, downtime, and inefficiencies.

Büchel underscores the importance of the “One Nolato” approach: “Our solutions are tailored to the unique needs of our clients. At the same time, we ensure our processes are resource-efficient and aligned with the highest ethical standards.”

- Nolato Treff

You might also e interested in

GROUP COMPANY

Nolato Treff

STORIES

Plastic a necessary part of society

STORIES