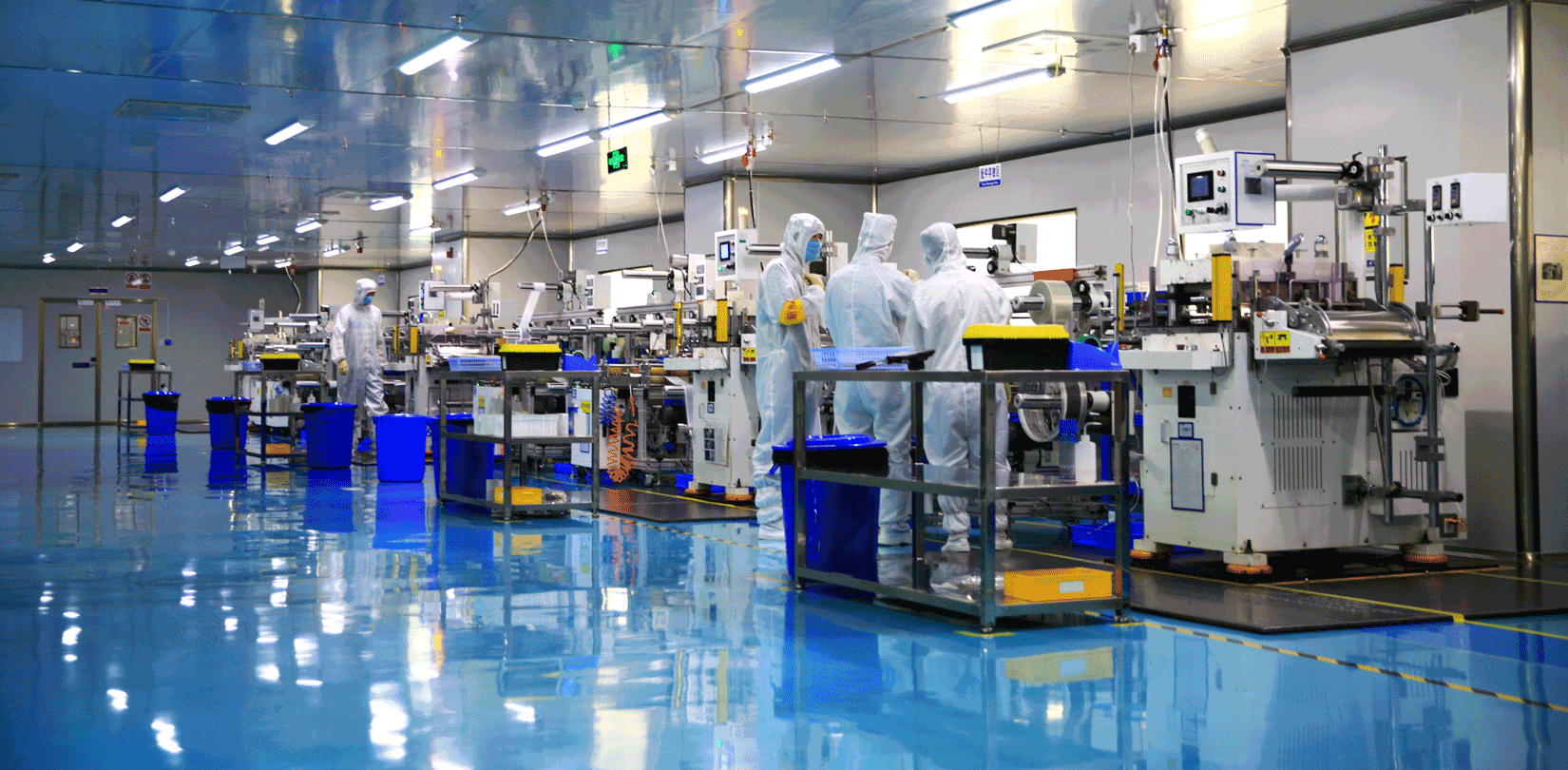

With two high-tech sites in China and one in Malaysia, Lövepac Converting offers manufacturing of small consumer electronic components and premium injection-molded ceramic parts.

Contact us

Sending Email...

GROUP COMPANY

Lövepac Converting

examples of products

- Ceramic mechanical parts

- Die-cut converting parts

- Laser-bonding products

- Small-size functional ME parts

- Smart wearable

Our sites

Beijing, China

Lövepac Converting

Shenzhen, China

Lövepac Technology

1st. Floor, No. 3 building, No.1 Lirong Rd.

Changyi Industrial Area, Xinshi Community, Dalang St. Longhua District

Shenzhen 518109, China

Penang, Malaysia

Nolato Malaysia

Penang Science Park,

14100 Simpang Ampat, Penang, Malaysia

Phone: +604 50 57 830

Contacts

SALES CONTACTS

Far East Asia

Southeast Asia

North America and Europe

Certifications

Certified environmental management systems are an important element of Nolato's sustainability work, and all companies are certified, acquired companies get a grace period to become certified. Download our certificates here.

Services

Laser-activated bonding solutions

1. Superior bonding strength

2. Outstanding waterproof performance

3. Strong resistance to impact

4. High rework yield

5. Ultra-slim bezel

products

Ceramic mechanical parts

▪ Premium appearance

▪ Diamond level durability

▪ 100% biologically compatible

▪ Zero skin allergy risk

▪ Optimal corrosion and scratch resistance

▪ Exceptional flatness and smoothness

RÖtt KRÖN earphones

Reality meets fantasy

RÖtt KRÖN is a new brand of wearables – consumer electronics that are not only high quality but also high fashion.

This product is a showcase for the possibilities that Nolato offers customers. From ceramics to plastic, from mechanical to cosmetic options, and from molds to integrated electronics. We want to inspire our current and future consumer electronics customers to think a little outside the box. And to use the capabilities that exist to stand out from the crowd.

Products

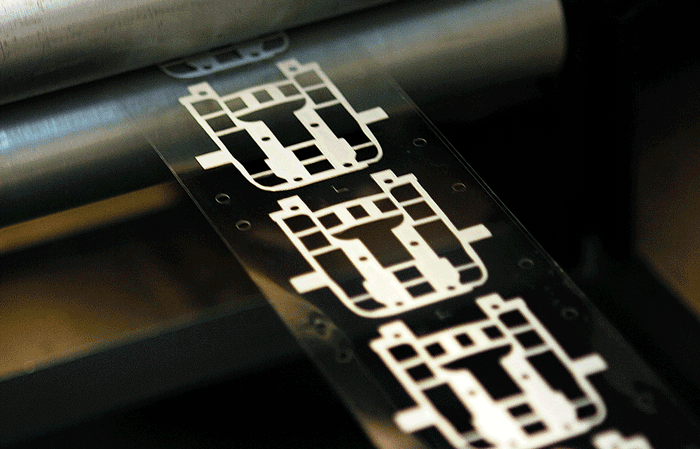

Die-cut converting parts

▪ Any layout to customer requirements

▪ Diversified lamination solutions

▪ Special bezel-cutting process

▪ No restrictions on product structure

products

Small functional mechanical components

Read more about our ceramic solutions and services

CAREERS AT NOLATO

Join our team

Explore careers in China

Stories

STORIES

95% of Nolato's carbon dioxide emissions are indirect and fall within Scope3

STORIES

We aim to reuse and recycle as much as possible in a constant loop

STORIES

Simulation is the key to optimization

Would you like us to contact you instead?

Please fill in the form and select your preferred method of contact and we will get back to you as soon as possible.

You might also be interested in

SERVICE

Ceramic injection molding

INDUSTRY

Consumer Electronics

SERVICE